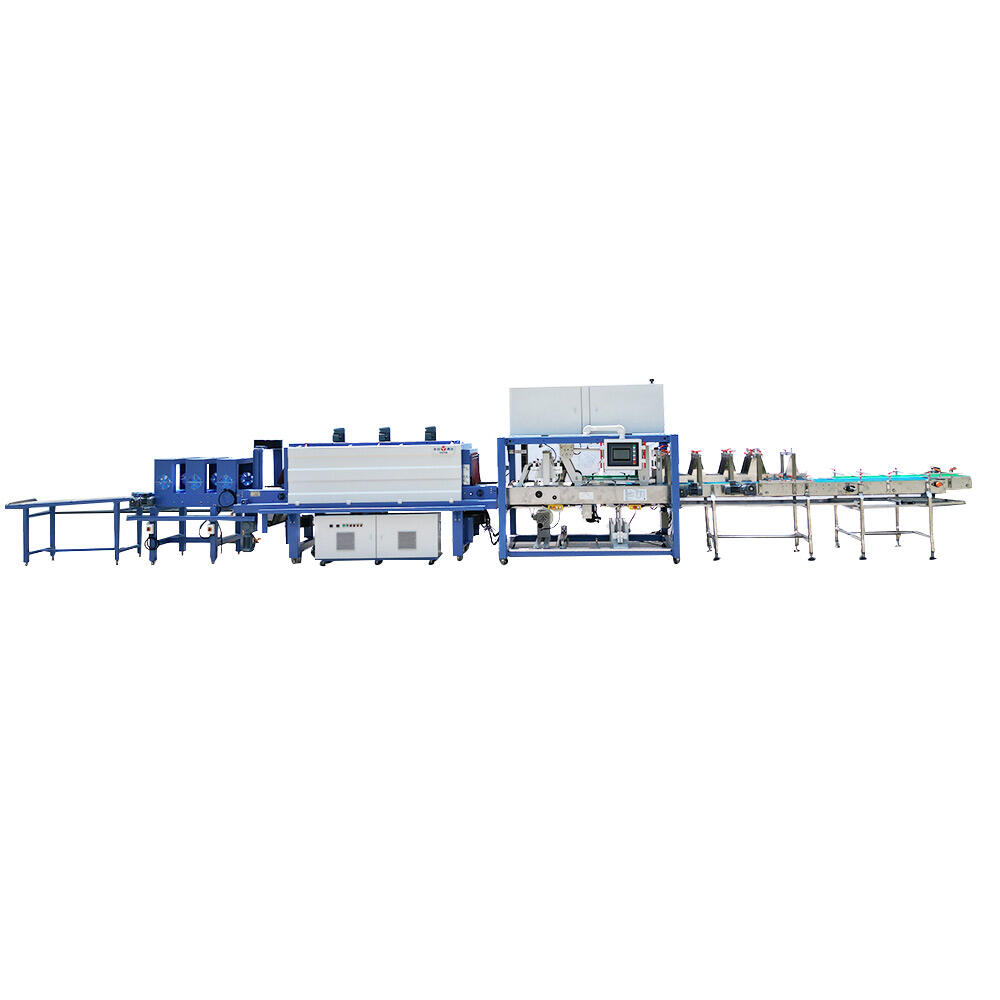

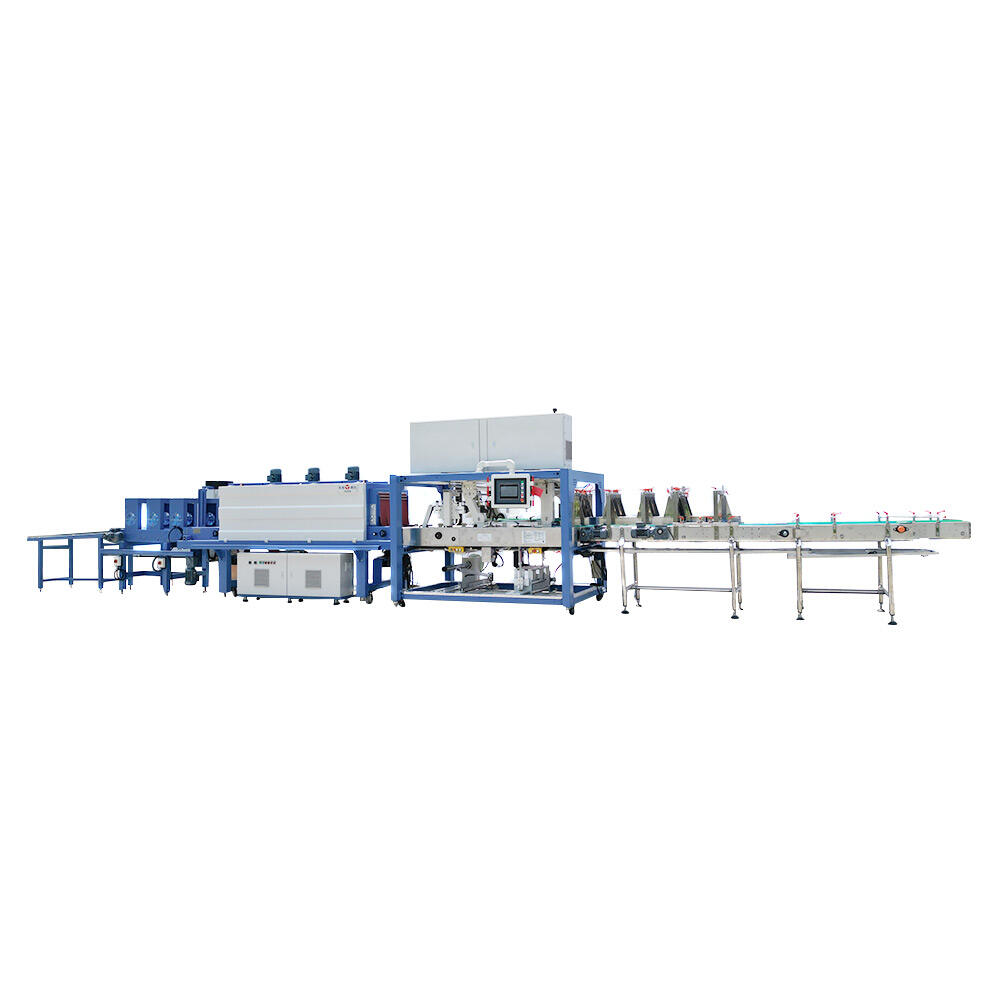

shrink wrap machine for sale

The shrink wrap machine for sale represents a cutting-edge solution in packaging technology, designed to meet the diverse needs of modern businesses. This versatile equipment utilizes advanced heat-shrinking technology to create secure, professional-looking packages for various products. The machine features a precise temperature control system, allowing operators to adjust settings according to different packaging materials and product requirements. With its robust stainless steel construction, the system ensures durability and long-term reliability in demanding industrial environments. The machine accommodates various product sizes through its adjustable sealing bars and conveyor system, making it ideal for both small-batch operations and high-volume production lines. Its user-friendly interface enables quick operation adjustments and monitoring of crucial parameters, while the integrated safety features, including emergency stop buttons and thermal protection, ensure operator safety. The system's efficient heating elements provide uniform shrinkage, resulting in tight, professional seals that enhance product presentation and protection. Additionally, the machine incorporates energy-saving features that optimize power consumption during operation, making it both environmentally conscious and cost-effective.