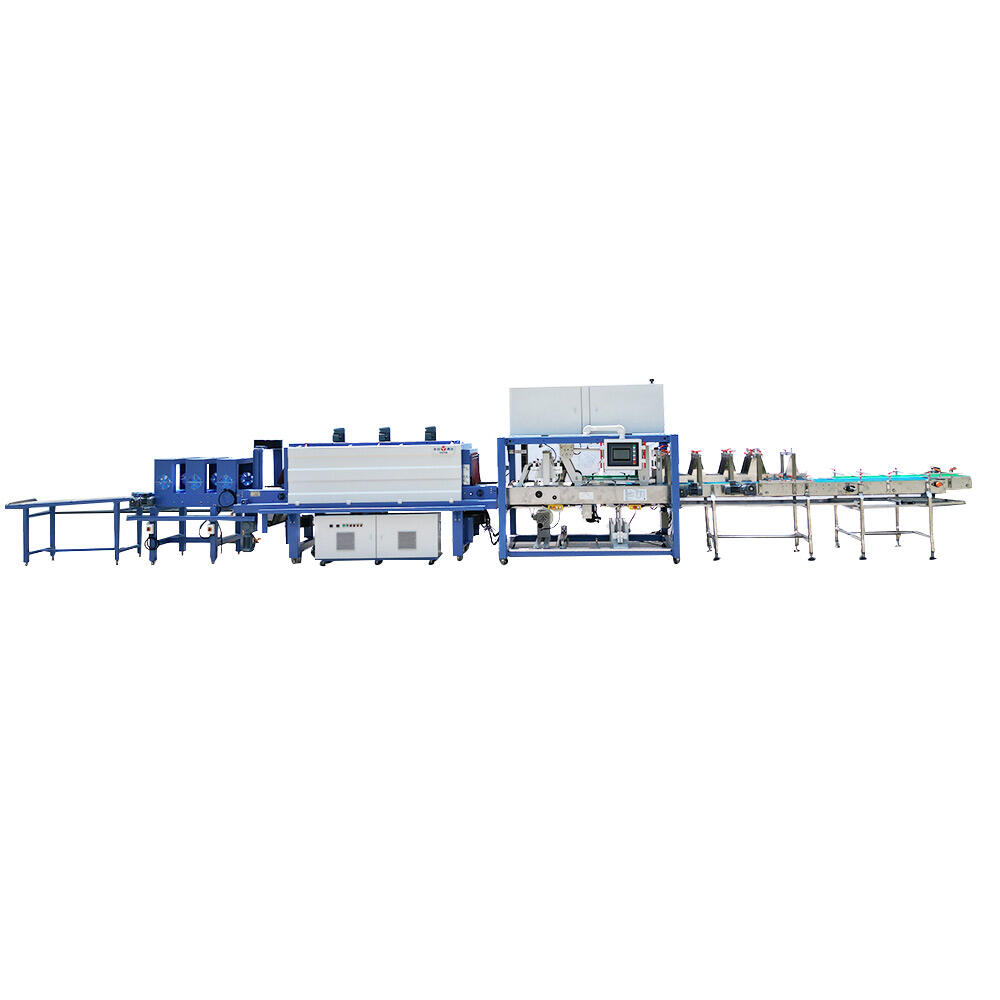

small shrink wrap machine

The small shrink wrap machine represents a compact and efficient solution for businesses seeking professional packaging capabilities. This versatile equipment utilizes advanced heat-shrinking technology to create seamless, professional-looking packaging for various products. Operating through a straightforward process, the machine applies controlled heat to specially designed shrink film, causing it to contract uniformly around items for a secure, attractive finish. The system typically includes an adjustable temperature control mechanism, allowing users to accommodate different film thicknesses and product types. Key components include a heating chamber, temperature regulation system, and a conveyor mechanism for smooth product movement. The machine's compact footprint makes it ideal for small to medium-sized operations, while its precision controls ensure consistent results across various packaging applications. Modern small shrink wrap machines often incorporate energy-efficient heating elements and safety features such as automatic shut-off systems and cool-down cycles. These units can handle products of varying dimensions, from small retail items to bundled products, making them invaluable for businesses in sectors ranging from food service to retail and manufacturing. The technology's adaptability allows for both individual product wrapping and bulk packaging solutions, providing essential flexibility for diverse business needs.