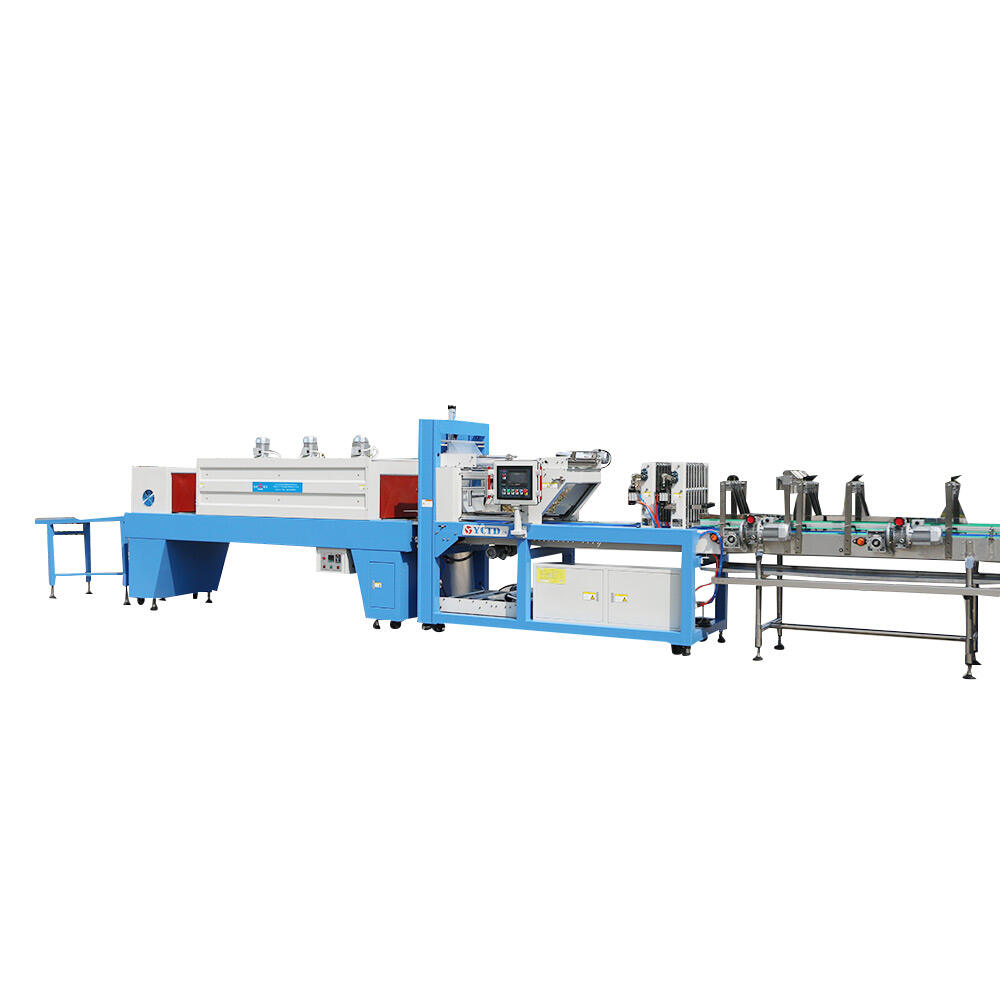

small shrink wrapping machine

The small shrink wrapping machine represents a compact yet powerful solution for businesses seeking efficient packaging solutions. This versatile equipment utilizes advanced heat shrink technology to create professional, tamper-evident packaging for various products. The machine features an adjustable sealing temperature control system, allowing operators to customize settings based on different film thickness and product requirements. With its space-saving design, the unit typically measures between 2-3 feet in length, making it ideal for small to medium-sized operations with limited floor space. The machine incorporates a precise cutting mechanism and a controlled heating chamber that ensures consistent shrinking results. Its user-friendly interface enables quick operation adjustments, while the built-in cooling system prevents overheating during continuous operation. The machine can handle various shrink film types, including PVC, POF, and PE materials, providing flexibility in packaging options. Most models can process items up to 15 inches in width and accommodate different product heights, making them suitable for packaging books, boxes, cosmetics, food items, and retail products.