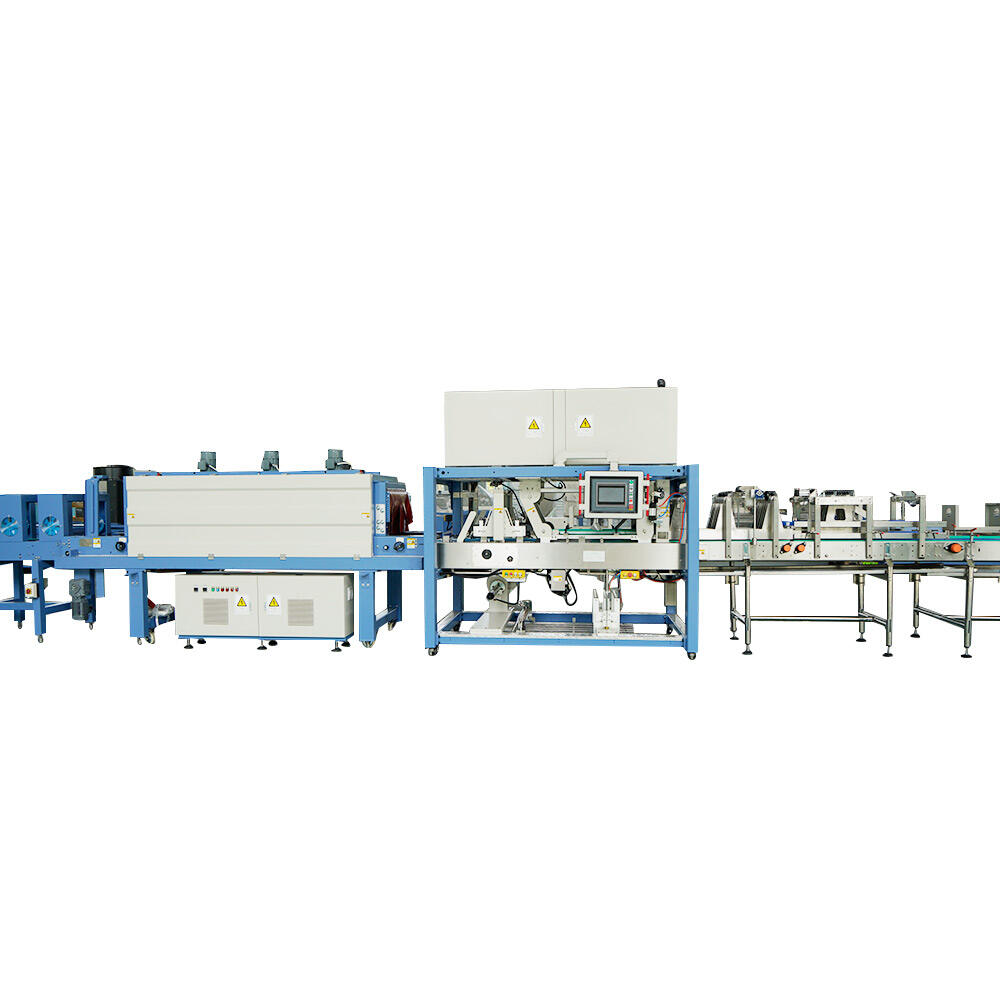

tray packaging machine

The tray packaging machine represents a pinnacle of modern packaging automation, designed to efficiently handle various products in tray-based packaging solutions. This sophisticated equipment integrates multiple functions including tray forming, product loading, and sealing in a single, streamlined process. The machine utilizes advanced servo motor technology to ensure precise control and consistent performance, capable of processing different tray sizes and configurations with minimal changeover time. Its modular design incorporates smart sensors and PLC control systems, enabling real-time monitoring and adjustments during operation. The machine excels in packaging applications across diverse industries, from food and beverage to pharmaceuticals and consumer goods. It can handle various packaging materials, including plastic, cardboard, and foam trays, with the capability to process both rigid and flexible packaging materials. The system's hygienic design features stainless steel construction and easy-access panels for cleaning and maintenance, making it particularly suitable for food packaging operations. With production speeds reaching up to 25 trays per minute, depending on the model and configuration, the machine offers significant throughput while maintaining packaging quality and integrity.