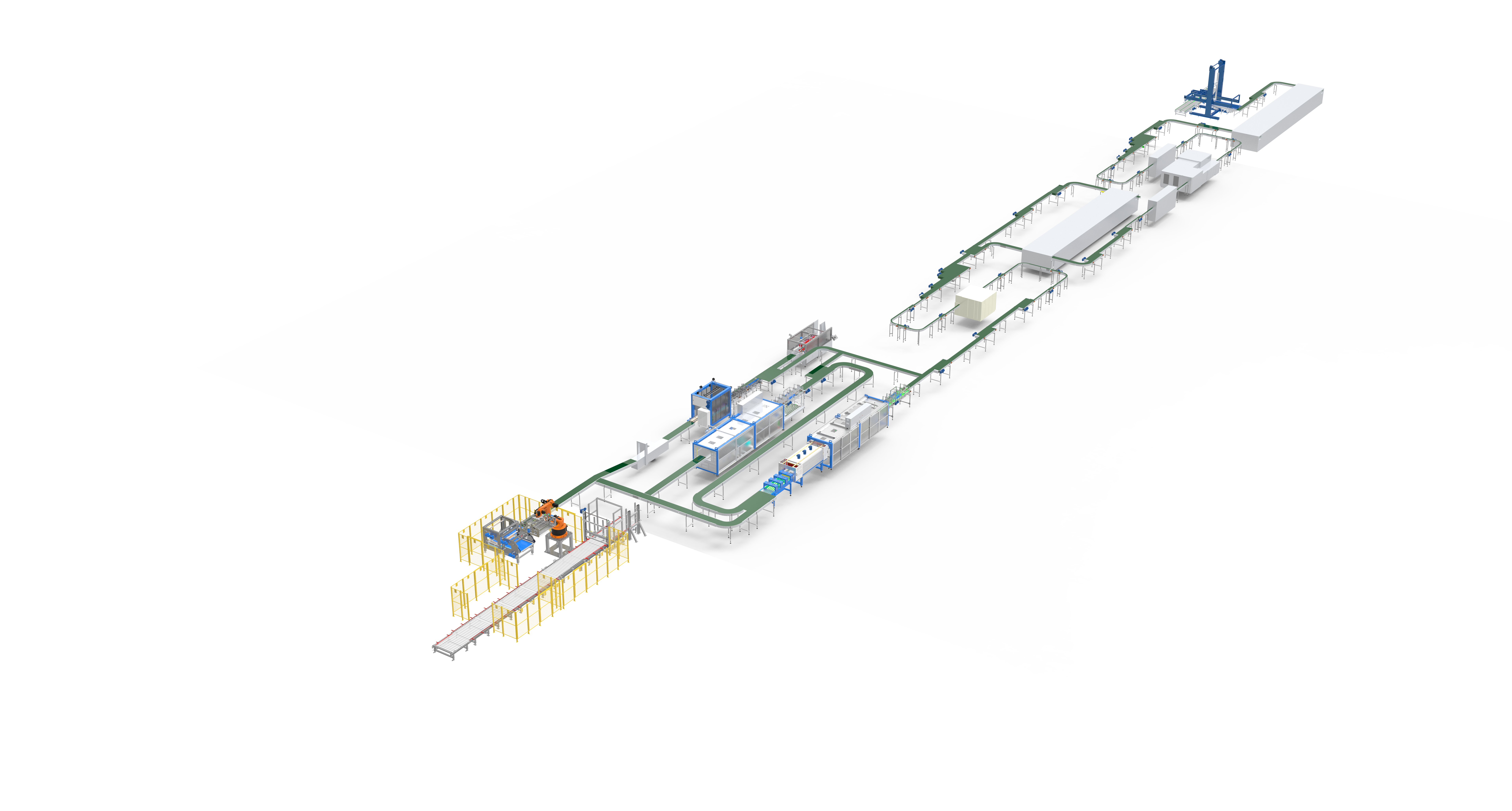

tray packaging plants

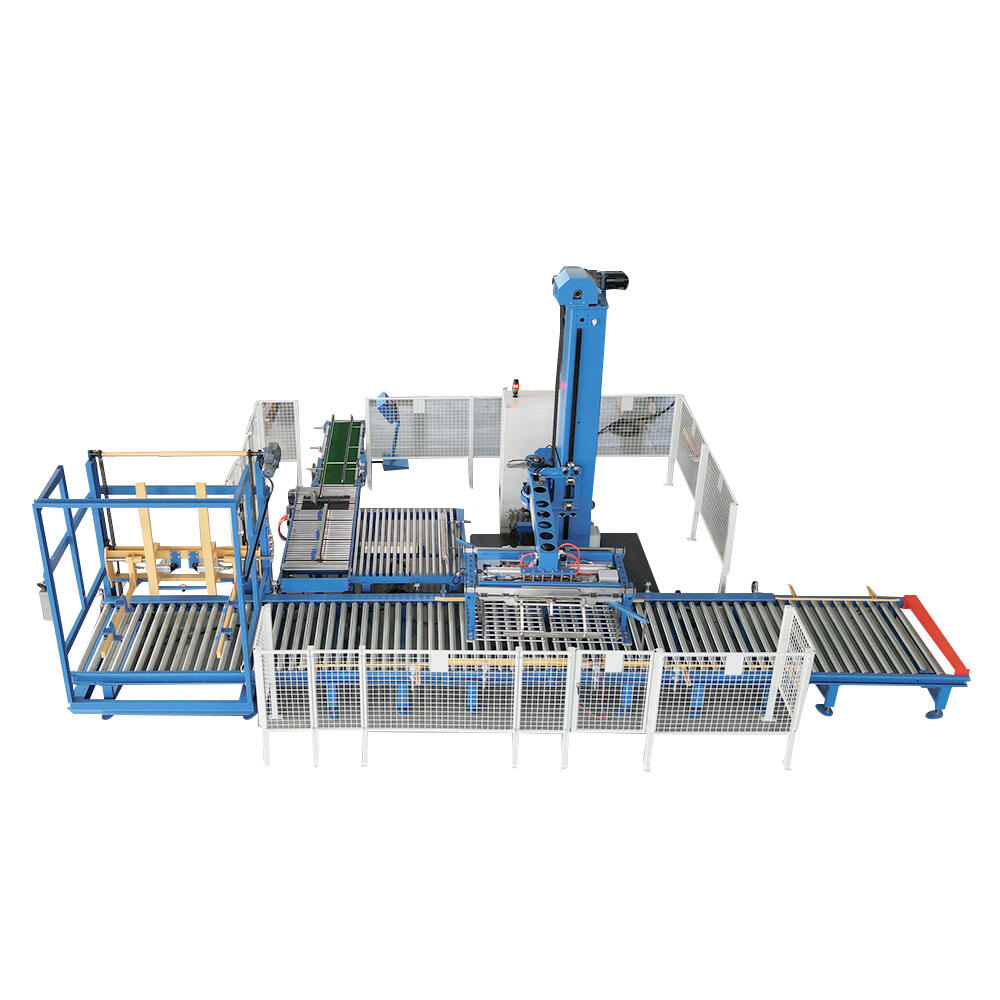

Tray packaging plants represent state-of-the-art automated systems designed to efficiently package products in pre-formed trays. These sophisticated facilities integrate multiple processes, including tray denesting, product loading, quality inspection, sealing, and labeling, all within a streamlined production line. The plants utilize advanced conveyor systems, robotic arms, and precision control mechanisms to ensure accurate product placement and consistent packaging quality. Modern tray packaging plants incorporate smart sensors and monitoring systems that maintain optimal operating conditions while detecting any irregularities in the packaging process. The facilities can handle various tray sizes and materials, from plastic to biodegradable options, offering flexibility in packaging solutions. These plants typically feature modular designs that allow for easy maintenance and future upgrades. The integration of IoT technology enables real-time monitoring and data collection, facilitating predictive maintenance and performance optimization. With throughput rates ranging from 20 to 200 trays per minute, these plants can accommodate different production scales while maintaining high precision and reliability. The systems also include quality control stations equipped with vision systems and weight checkers to ensure product integrity and packaging compliance.