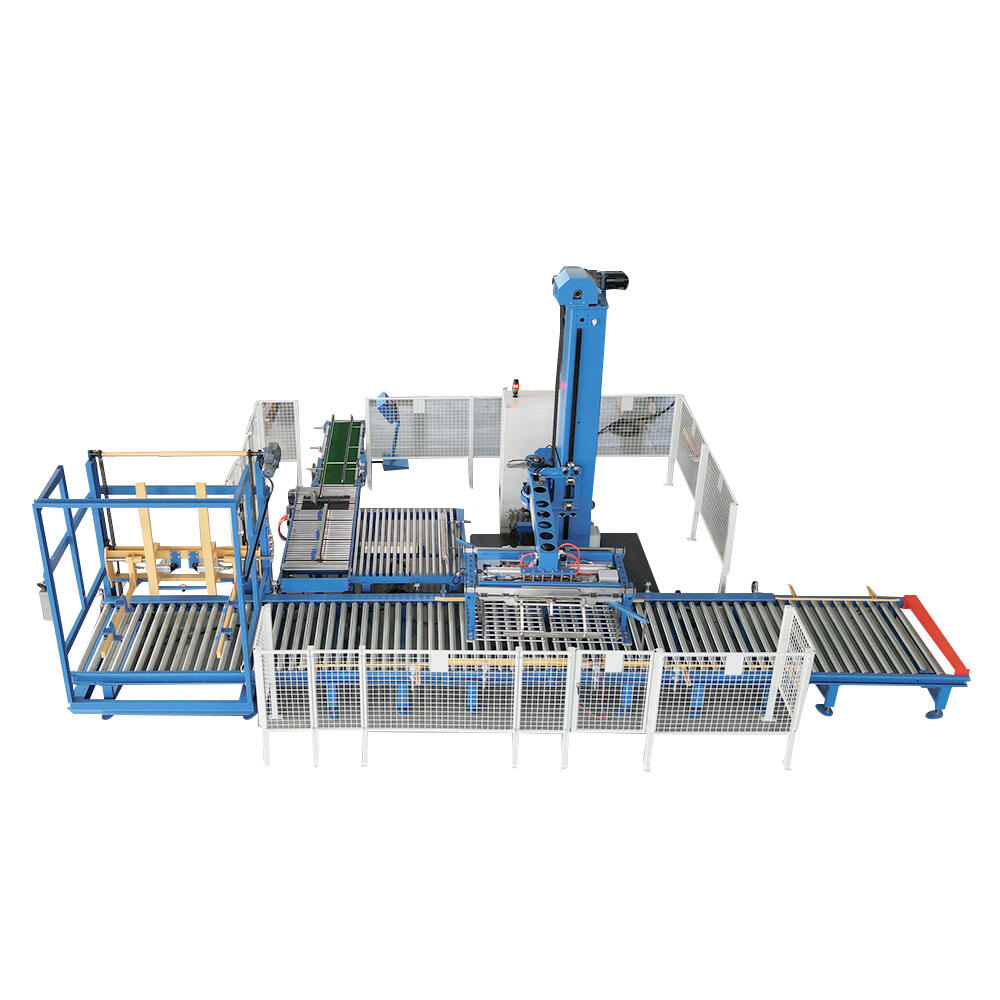

ماكينة تحميل وتفريغ البالات

يمثل نظام التحميل على الألواح (Palletizer) وتفريغ الألواح (Depalletizer) تكنولوجيا متقدمة في مجال مناولة المواد، صُمّم لتشغيل عمليات تكديس وفك المنتجات على الألواح تلقائيًا. يقوم جهاز التحميل على الألواح بتنظيم وتكديس المنتجات أو الصناديق أو الحاويات على الألواح بأسلوب دقيق مبرمج، بينما يقوم جهاز تفريغ الألواح بالعملية العكسية من خلال إزالة العناصر من الألواح بطريقة منهجية. تعتمد هذه الأنظمة على أجهزة استشعار متطورة وروبوتات وأنظمة نقل (Conveyor) لمناولة منتجات بأحجام وأوزان مختلفة بدقة استثنائية. تتضمن حلول التحميل والتفريغ الحديثة ميزات متقدمة مثل تقنية التعرف على الأنماط (Pattern Recognition) وتشكيل الطبقات تلقائيًا وأنظمة تحكم ذكية يمكنها التكيف مع مواصفات مختلفة للمنتجات. تعمل هذه الأنظمة من خلال مزيج من المكونات الميكانيكية والإلكترونية، بما في ذلك المحركات المؤازرة (Servo Motors) والأنظمة الهوائية (Pneumatic Systems) وأجهزة التحكم المنطقية القابلة للبرمجة (PLCs) التي تضمن تشغيلًا سلسًا وثابتًا. تُستخدم هذه الأنظمة على نطاق واسع عبر مختلف الصناعات، بما في ذلك الصناعات الغذائية والدوائية والسلع الاستهلاكية والتصنيع، حيث تُسهم بشكل كبير في تعزيز الكفاءة التشغيلية وتقليل متطلبات العمل اليدوي. يمكن لهذه التكنولوجيا التعامل مع أنواع متعددة من المنتجات وتكوينات الألواح المختلفة، مما يوفر مرونة في بيئات الإنتاج مع الحفاظ على معايير السلامة الصارمة وسلامة المنتجات طوال العملية.