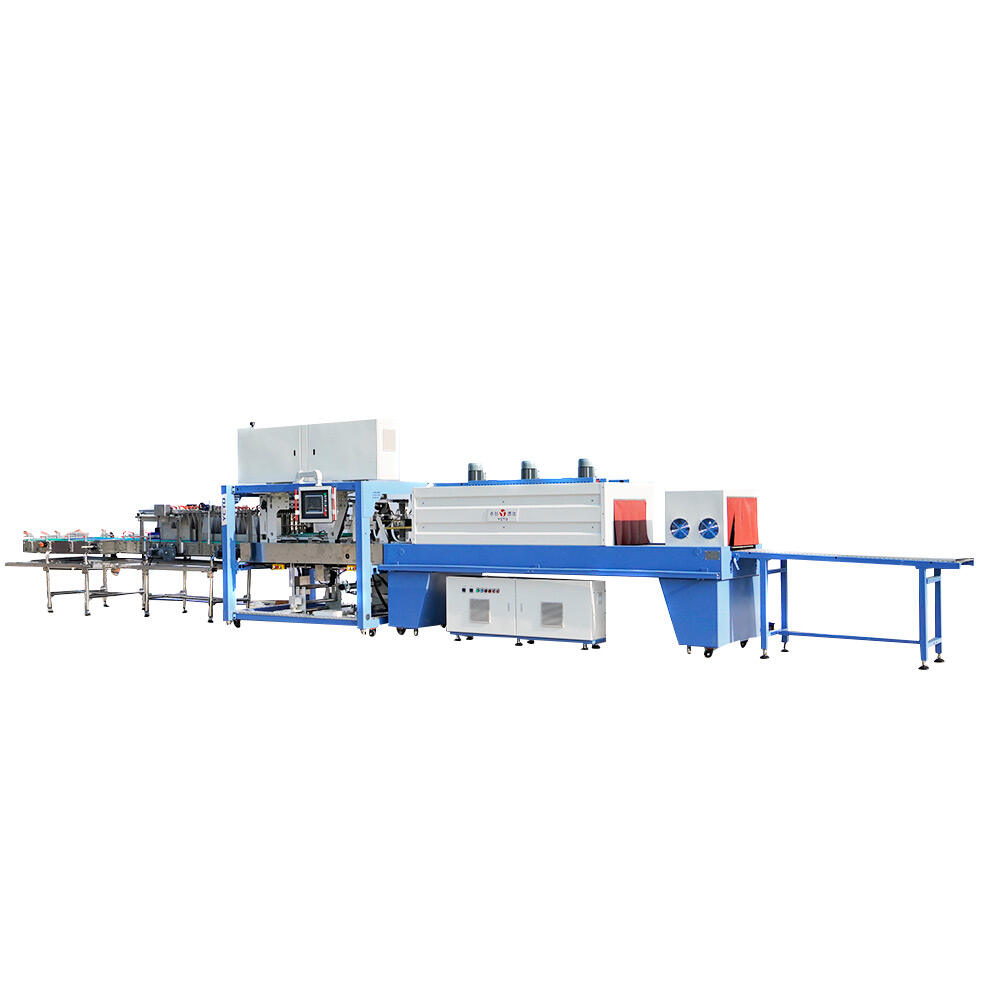

shrink machine for packing

A shrink machine for packing represents a cornerstone of modern packaging automation, designed to efficiently wrap and protect products using heat-shrinkable films. This versatile equipment operates by applying controlled heat to specially designed plastic films, causing them to contract and conform tightly around products of various sizes and shapes. The machine typically consists of several key components including a sealing system, a heating tunnel, and a conveyor mechanism that work in harmony to deliver consistent packaging results. The technology employs precise temperature control systems that ensure optimal shrinkage without damaging the product or compromising the film's integrity. Modern shrink machines are equipped with adjustable temperature settings, variable speed controls, and multiple heating zones to accommodate different packaging requirements. These machines can handle a wide range of products, from small consumer goods to large industrial items, making them indispensable in industries such as food and beverage, pharmaceuticals, cosmetics, and retail. The process begins with product placement and film wrapping, followed by heat application that triggers the shrinking action, resulting in a tight, professional finish that enhances product presentation while providing protection during storage and transportation.