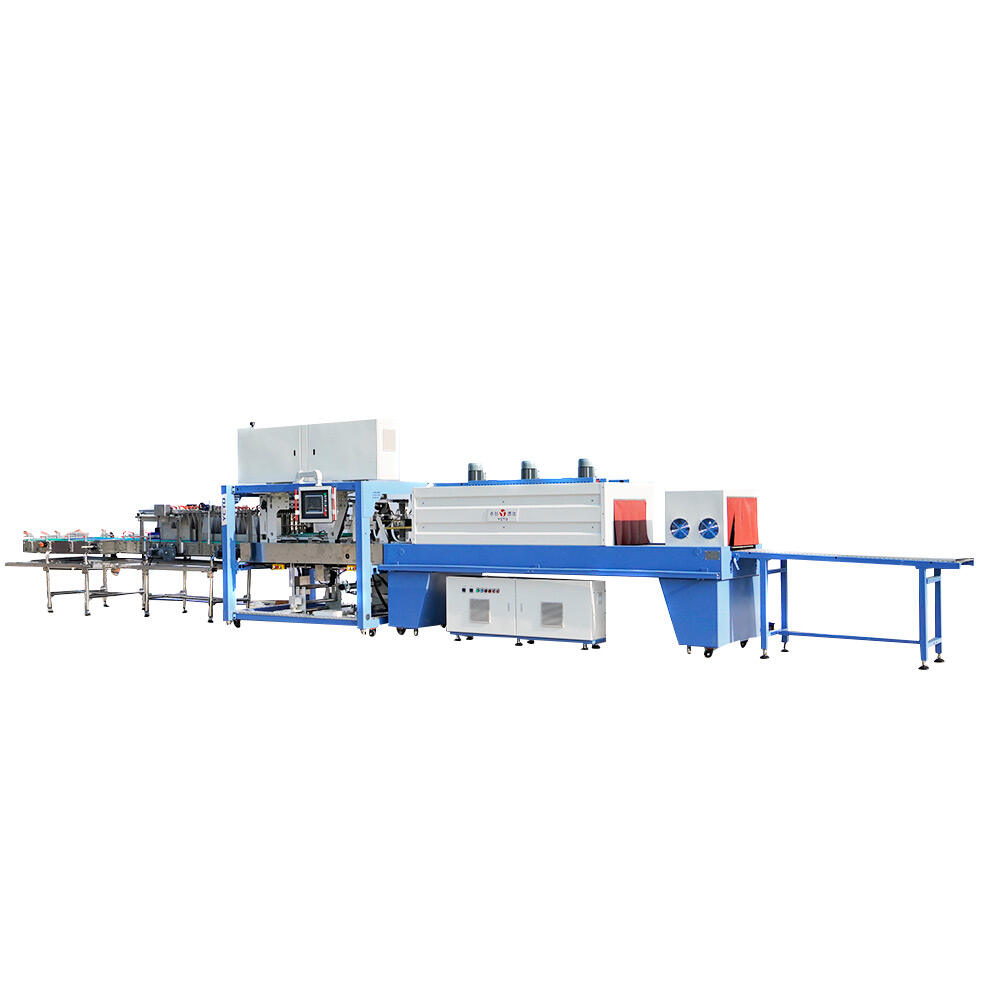

beer bottle shrink wrap machine

A beer bottle shrink wrap machine is an advanced packaging solution designed specifically for the beverage industry. This sophisticated equipment automates the process of applying protective shrink wrap material around beer bottles, ensuring secure packaging and professional presentation. The machine incorporates a precise thermal control system that carefully applies heat to shrink the wrap material, creating a tight, tamper-evident seal around single bottles or multipacks. Operating on a continuous feed system, it can handle various bottle sizes and configurations, with adjustable settings to accommodate different packaging requirements. The machine features an efficient conveyor system that smoothly transports bottles through multiple stages: wrap feeding, positioning, sealing, and heat shrinking. Advanced sensors monitor the process, ensuring consistent wrap application and preventing material waste. The technology includes automated cutting mechanisms that precisely measure and cut shrink wrap material, while the heat tunnel maintains optimal temperature distribution for uniform shrinkage. Modern models incorporate user-friendly touch screen interfaces for easy operation and quick format changes, making it suitable for both small craft breweries and large-scale beverage manufacturers.