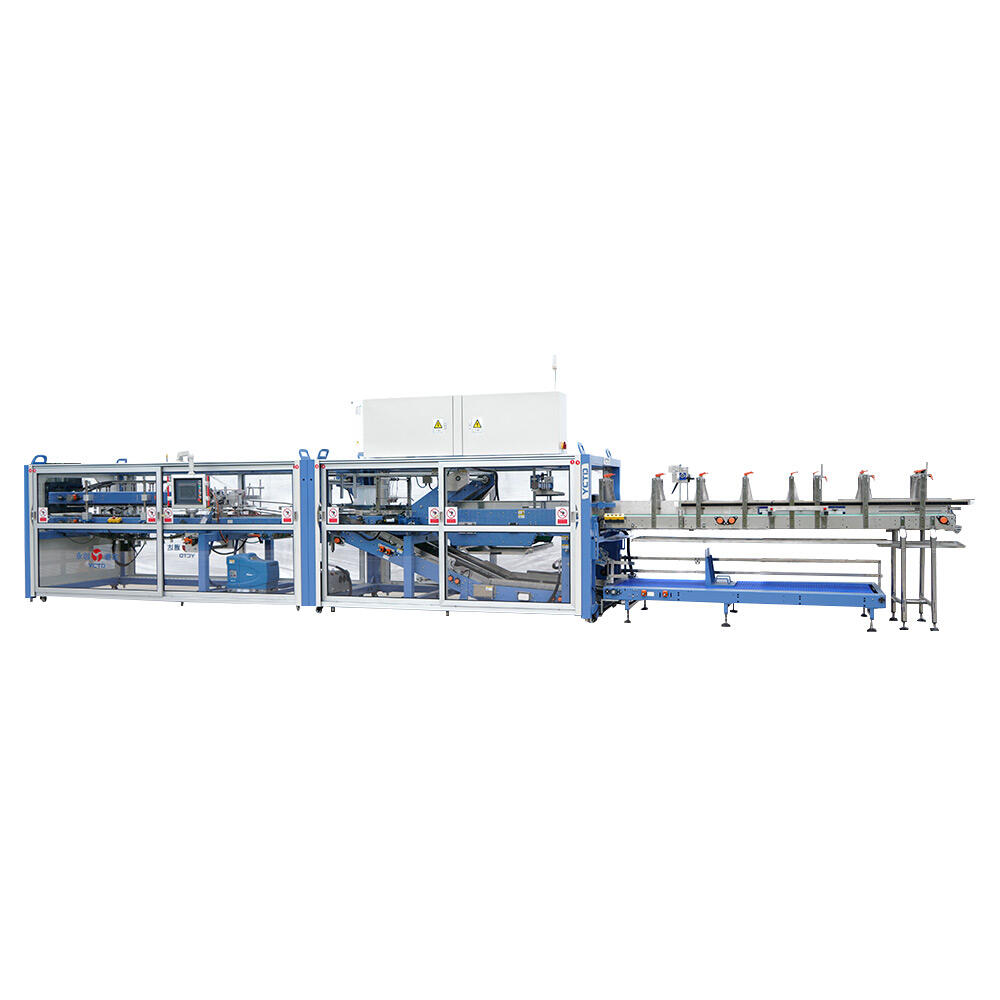

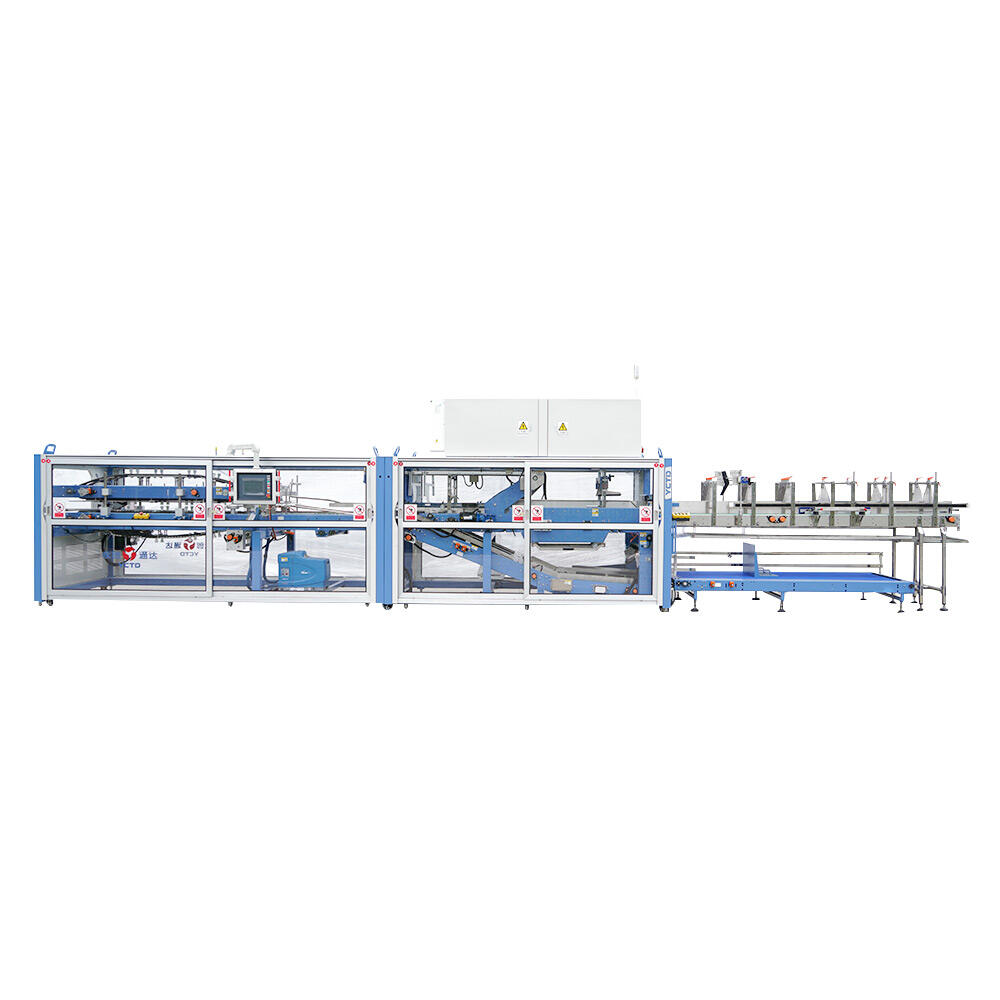

case packing equipment

Case packing equipment represents a crucial component in modern packaging operations, offering automated solutions for efficiently packing products into cases, cartons, or boxes. These sophisticated machines integrate seamlessly into production lines, handling various package types and sizes with precision and consistency. The equipment utilizes advanced servo motors and control systems to ensure accurate product placement and gentle handling, minimizing damage during the packing process. Case packers can accommodate multiple product configurations, including vertical, horizontal, and random pack patterns, making them versatile for different industry requirements. The machines feature automatic case erecting, product loading, and case sealing capabilities, significantly reducing manual labor requirements while maintaining high production speeds. Built with robust engineering principles, modern case packing systems incorporate safety features such as emergency stops, guard doors, and monitoring systems to protect operators and maintain production integrity. The equipment's adaptability allows for quick changeovers between different product sizes and packaging formats, essential for facilities handling multiple SKUs. These systems can be integrated with vision systems for quality control and tracking purposes, ensuring proper product orientation and package integrity throughout the packing process.