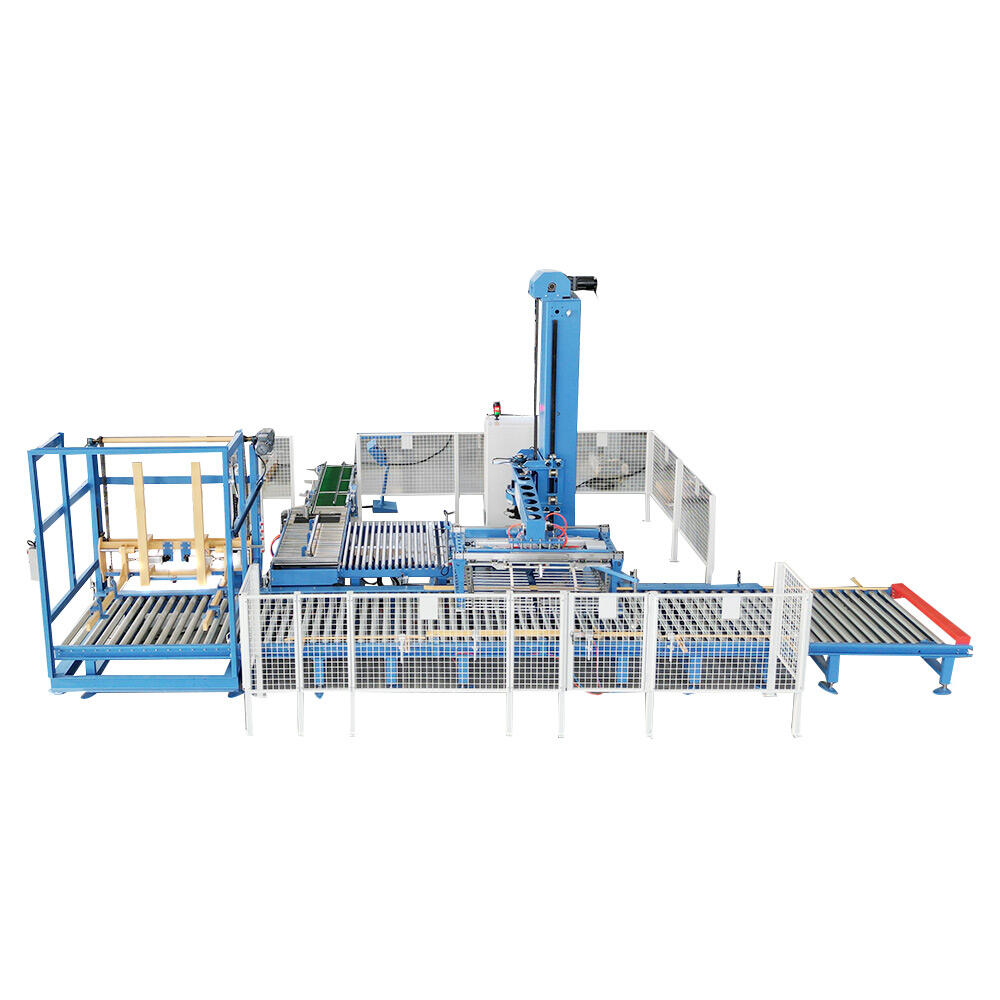

box conveyor

A box conveyor represents a sophisticated material handling solution designed to efficiently transport boxes, cartons, and packages across various industrial settings. This automated system comprises a series of powered rollers, belts, or chains that facilitate smooth and continuous movement of boxes along predetermined paths. The system's modular design allows for customizable configurations to meet specific facility layouts and operational requirements. Advanced features include variable speed controls, precision tracking mechanisms, and intelligent routing capabilities that enable seamless integration with existing warehouse management systems. The conveyor's robust construction typically incorporates high-grade materials ensuring durability and minimal maintenance requirements. Modern box conveyors are equipped with safety features such as emergency stop mechanisms, guard rails, and sensor systems that prevent package collisions and ensure worker safety. The technology can handle various box dimensions and weights, making it versatile for different industrial applications. Integration capabilities with scanning systems, sortation devices, and other automated equipment enhance its functionality in modern distribution centers. The system's efficient design minimizes energy consumption while maximizing throughput, contributing to overall operational efficiency.