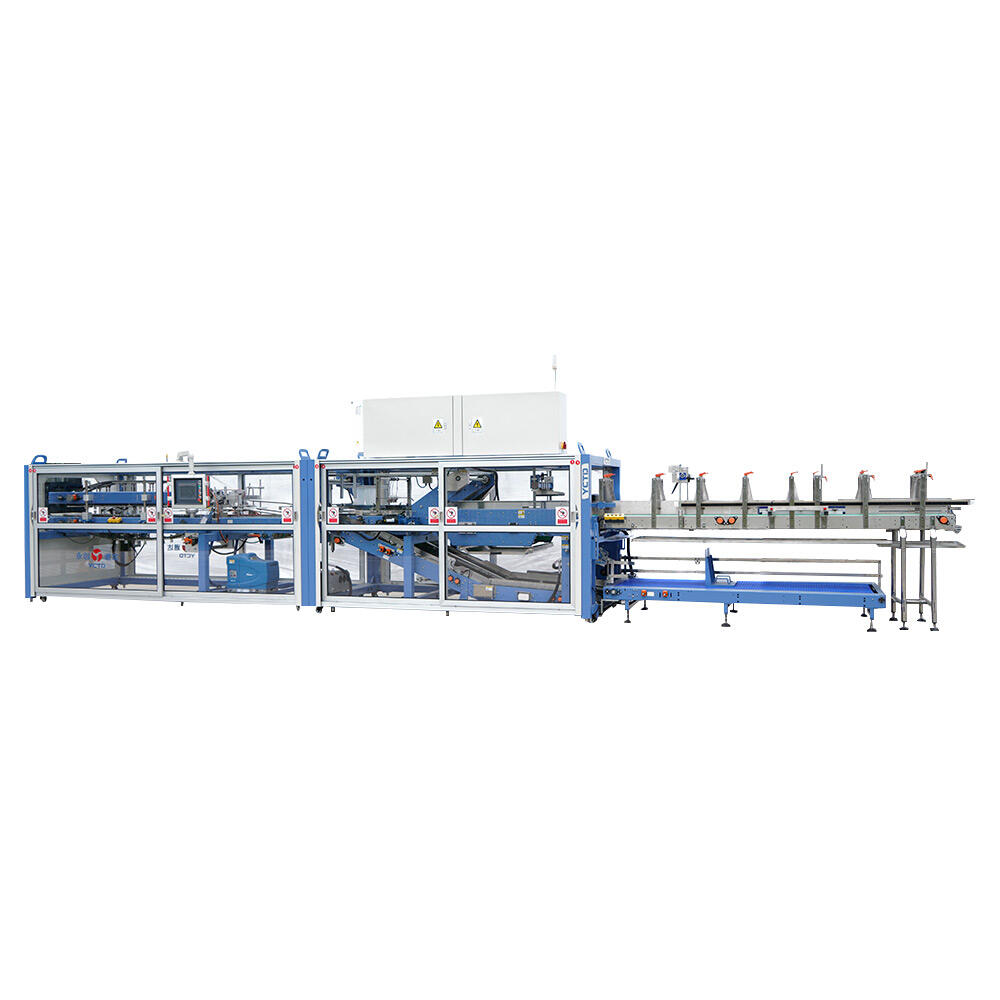

carton case packer

A carton case packer represents a sophisticated piece of automated packaging equipment designed to efficiently load products into shipping cases or cartons. This versatile machine streamlines the packaging process by automatically arranging and placing products into secondary packaging containers with precision and consistency. The system typically comprises multiple components, including a product infeed system, case erector, product collation mechanism, and case sealing unit. Modern carton case packers utilize advanced servo motors and intelligent control systems to achieve optimal performance and flexibility. These machines can handle various product types and sizes, from food and beverage containers to consumer goods packaging, operating at speeds of up to 30 cases per minute depending on the model and configuration. The technology incorporates sensors and vision systems to ensure accurate product placement and prevent damage during the packing process. Many models feature tool-less changeover capabilities, allowing quick adjustments for different product sizes and case formats. The integration of user-friendly HMI interfaces enables operators to monitor and control the entire packing process efficiently, while built-in safety features protect both operators and products during operation. These machines are particularly valuable in industries requiring high-volume packaging solutions, offering scalability and adaptability to meet evolving production needs.