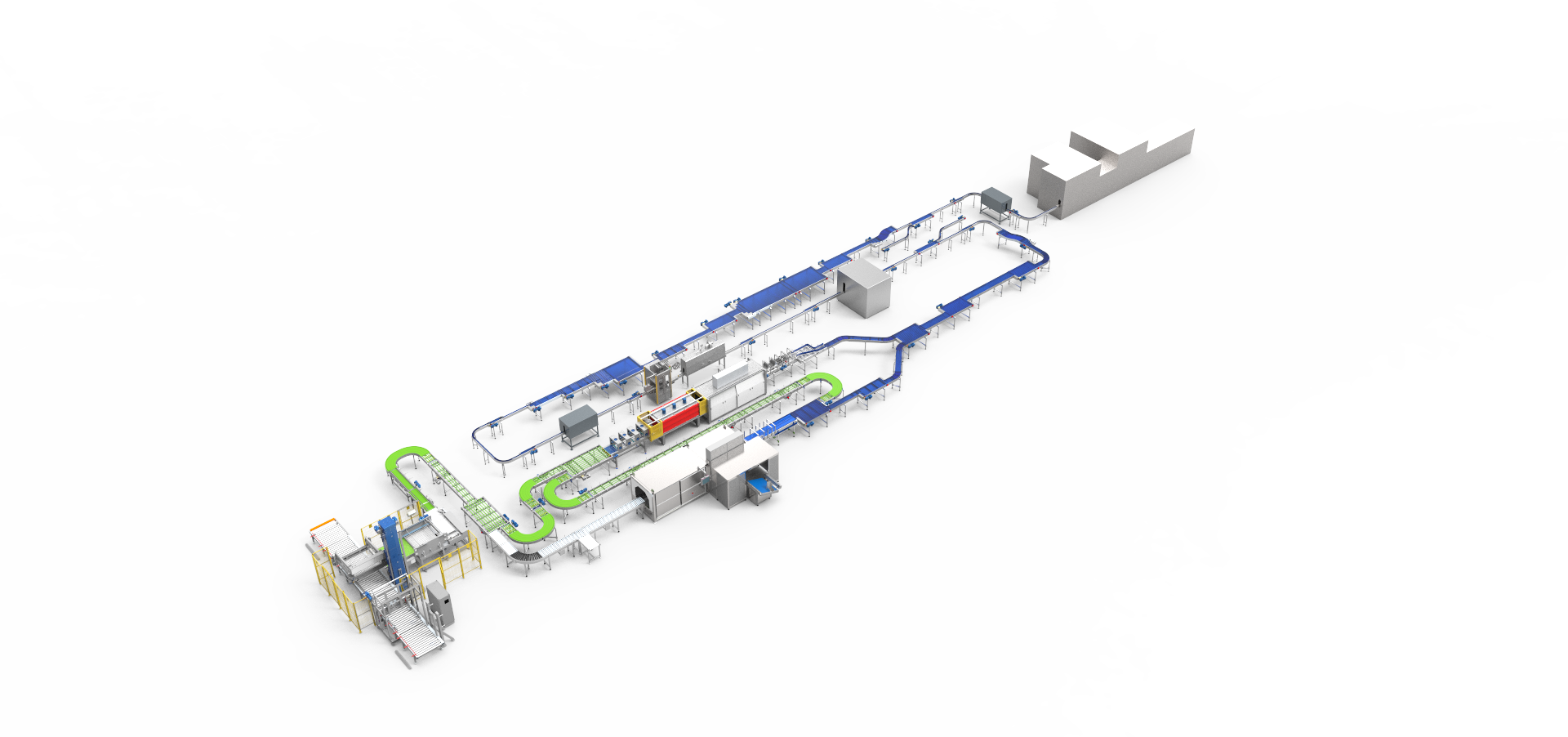

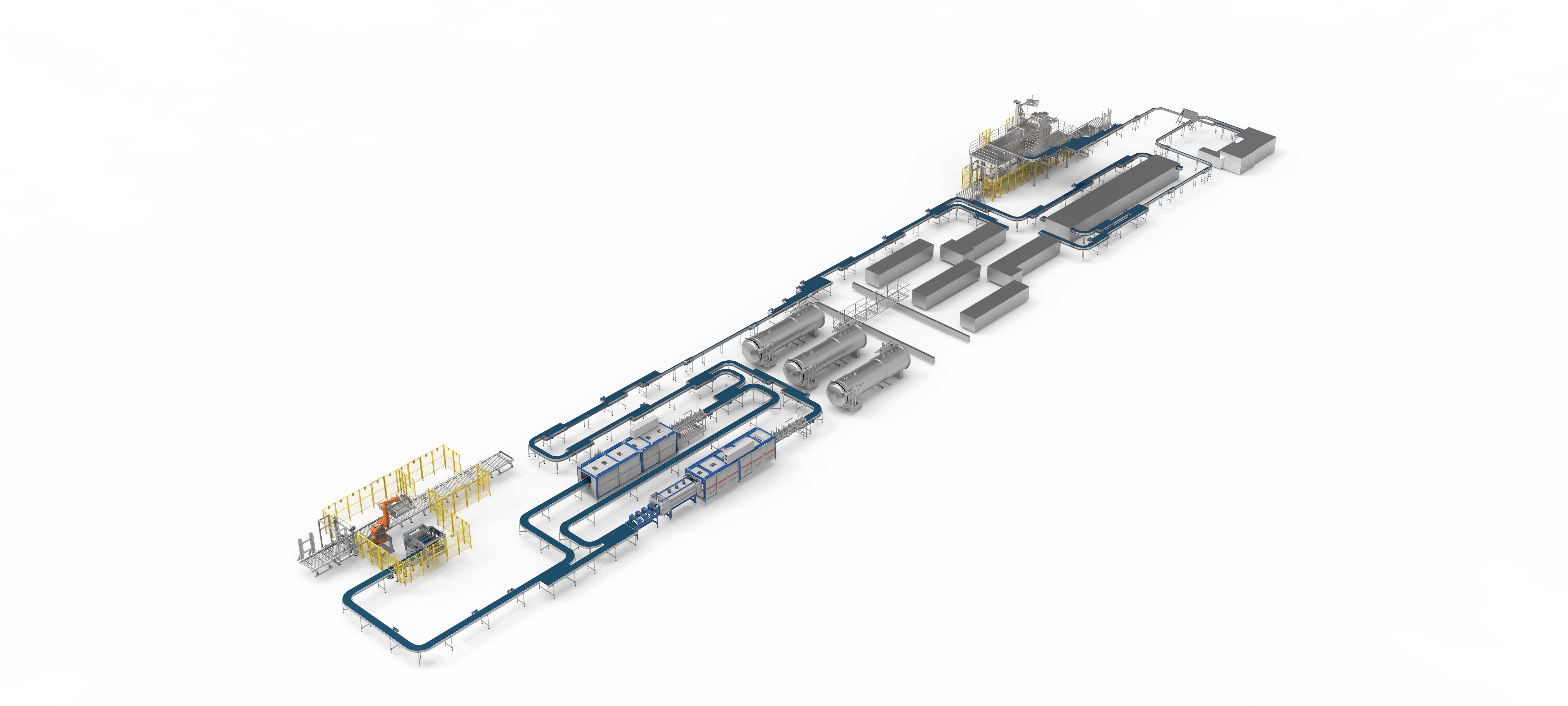

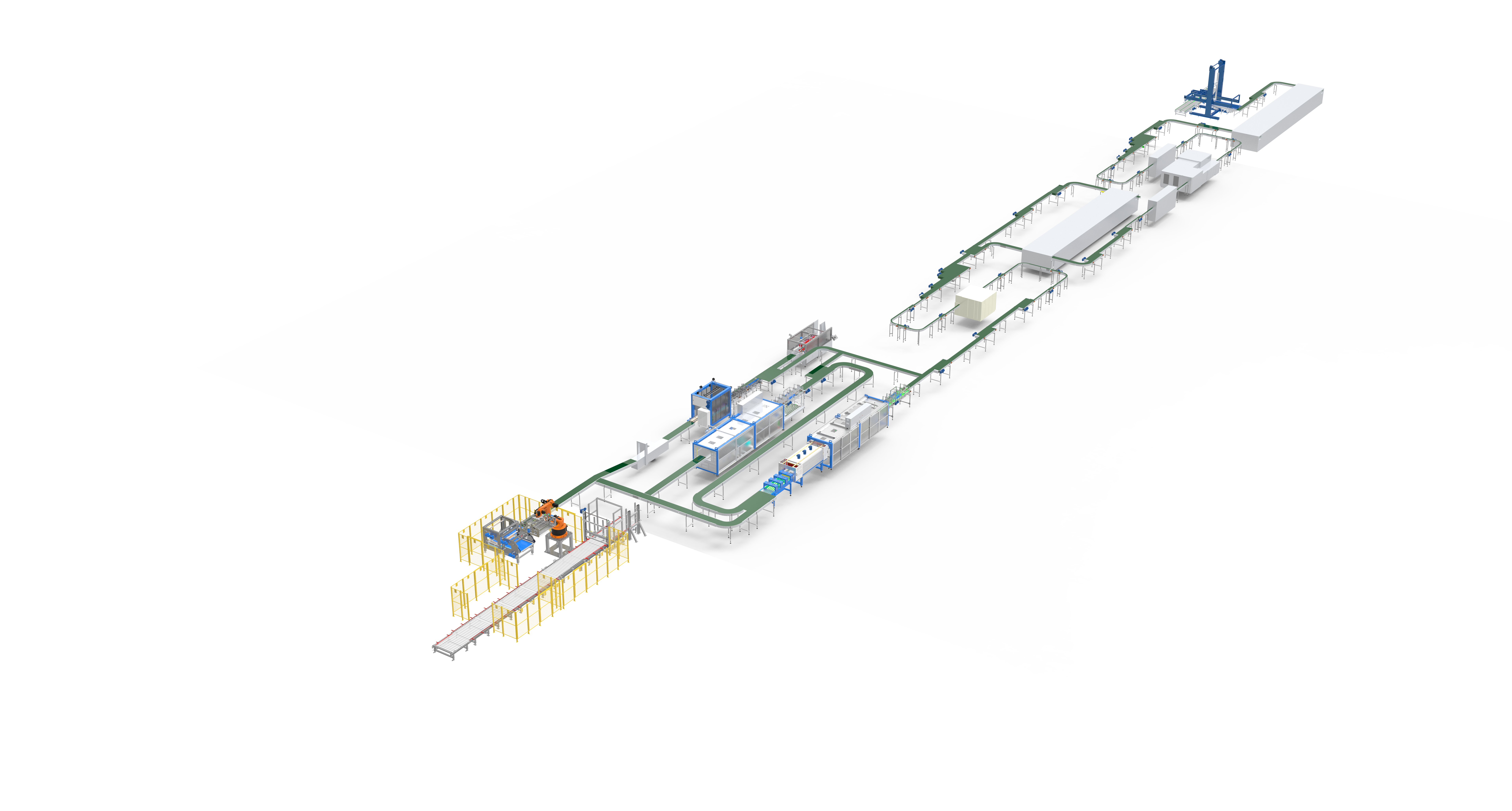

beverage production line

A beverage production line represents a sophisticated manufacturing system designed to efficiently process, fill, and package various types of drinks. This integrated system encompasses multiple stages, from initial liquid preparation to final packaging, ensuring consistent quality and high production output. The line typically begins with water treatment systems, followed by mixing and blending equipment that precisely combines ingredients according to specified recipes. Advanced automation technology controls the entire process, maintaining precise temperature, pressure, and flow rates throughout production. The system includes state-of-the-art filling machines capable of handling different container types and sizes, from glass bottles to plastic containers and aluminum cans. Quality control mechanisms, such as vision systems and weight checkers, are strategically positioned along the line to ensure product consistency and safety. The production line also features modern cleaning and sanitization systems that maintain strict hygiene standards, crucial for beverage manufacturing. With capabilities ranging from carbonated soft drinks to juices, dairy beverages, and energy drinks, these lines can be customized to meet specific production requirements and scale accordingly.