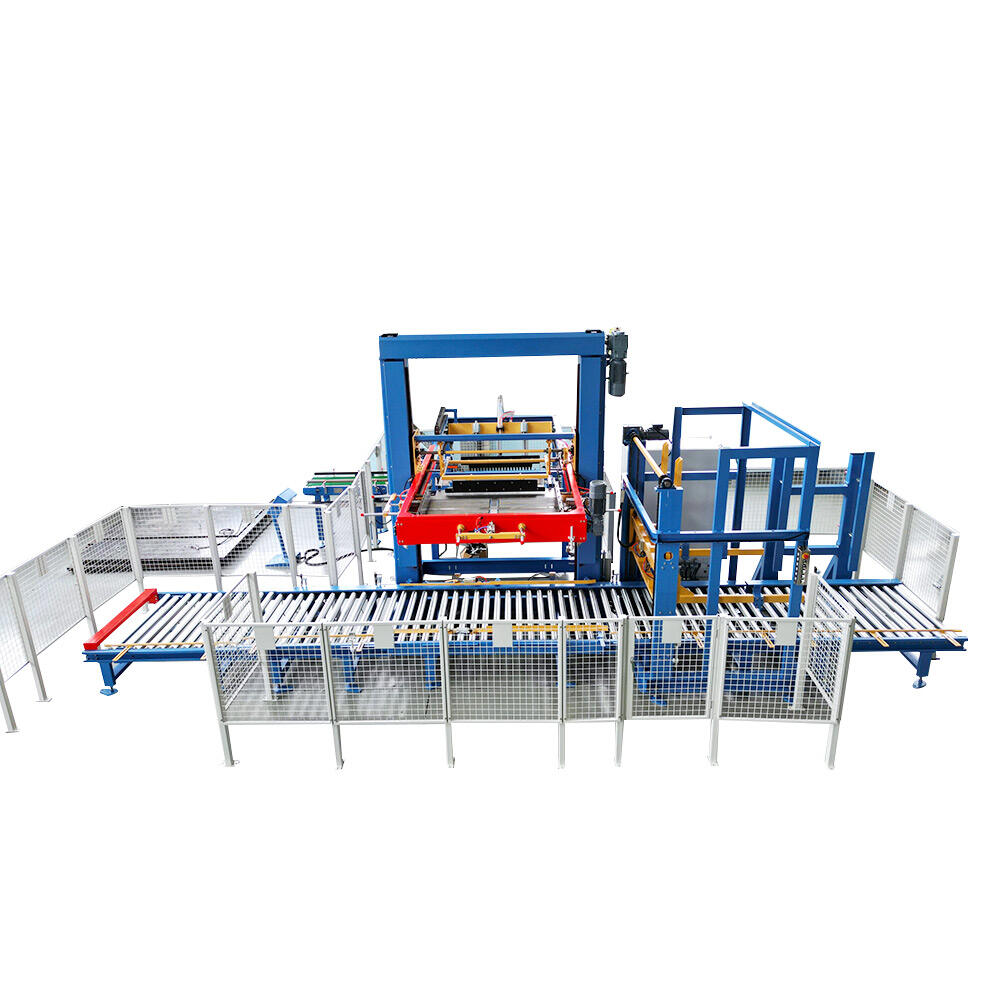

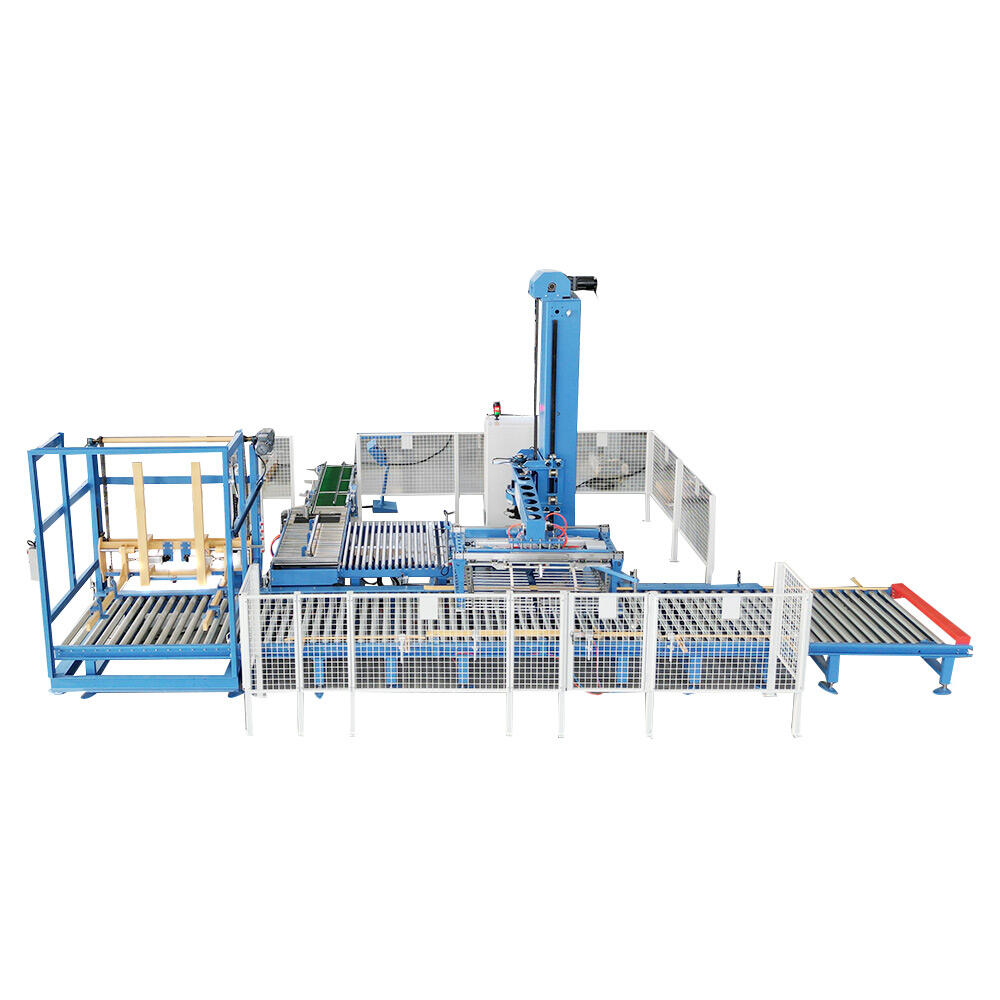

compact palletizer

A compact palletizer represents a revolutionary advancement in automated material handling systems, designed specifically for facilities where space optimization is crucial. This sophisticated machine efficiently arranges and stacks products onto pallets in a systematic manner, utilizing advanced sensors and precise mechanical components to ensure accurate placement. The system incorporates smart technology that enables it to handle various product sizes and configurations while maintaining a small footprint. Operating through a combination of conveyor systems, robotic arms, and programmable logic controllers, the compact palletizer can process multiple items simultaneously, significantly reducing manual labor requirements. Its modular design allows for seamless integration into existing production lines, while its intuitive interface enables operators to easily adjust settings and monitor performance. The machine's versatility extends to handling different pallet patterns and product types, from boxes and bags to containers and drums. Advanced safety features, including emergency stop systems and protective barriers, ensure operator protection while maintaining optimal productivity. The compact palletizer's efficient design not only maximizes space utilization but also enhances overall operational efficiency through consistent, precise, and reliable performance.