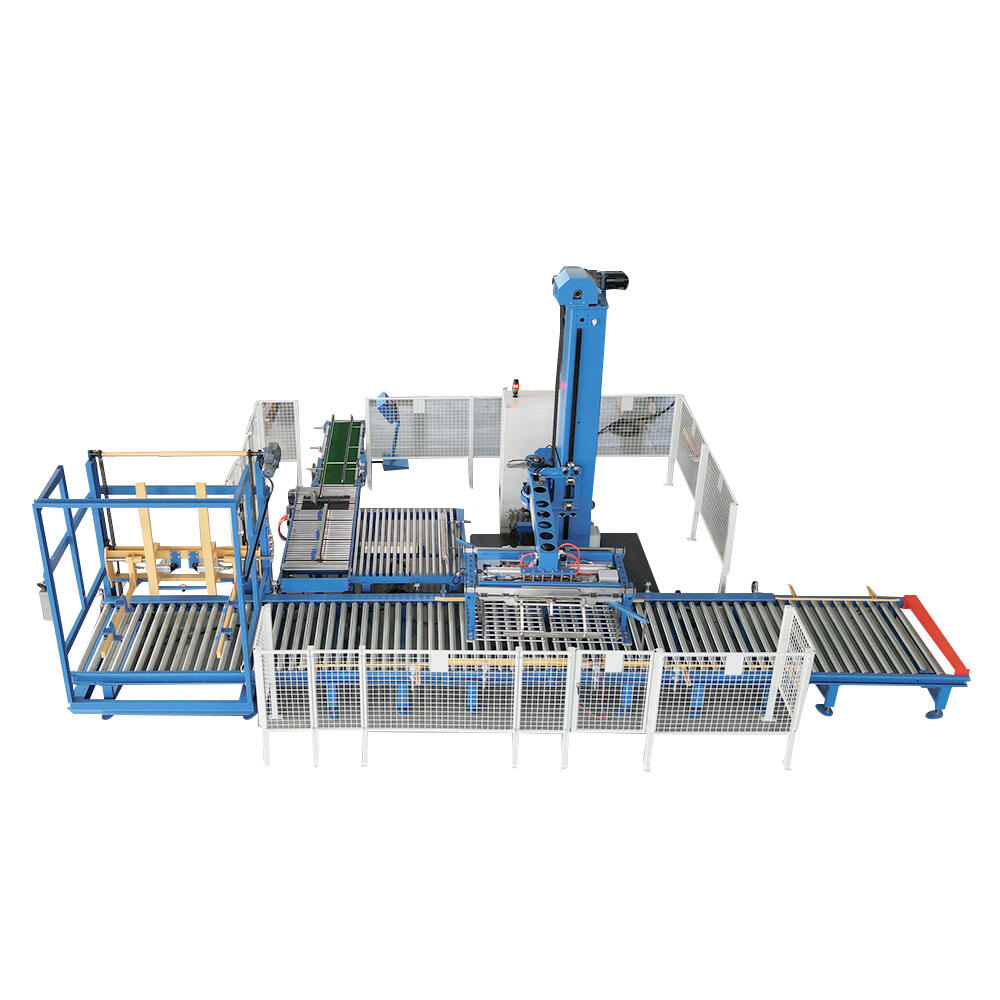

palletizer machine price

When exploring palletizer machine prices, it's essential to understand the comprehensive value these automated systems offer. Modern palletizer machines represent a significant investment in warehouse efficiency, typically ranging from $30,000 to $150,000 depending on specifications. These automated systems excel in systematically arranging and stacking products onto pallets, handling various load sizes and configurations. The price spectrum reflects different technological capabilities, from basic mechanical systems to advanced robotic solutions with smart features. Entry-level palletizer machines offer fundamental stacking capabilities, while premium models incorporate advanced features like pattern programming, multiple product handling, and integration with warehouse management systems. The price also accounts for crucial factors such as throughput capacity, which can range from 10 to 200 cases per minute, and the level of customization required for specific industry applications. Manufacturers often consider the total cost of ownership, including installation, maintenance, and operational expenses when evaluating palletizer machine prices. The investment typically delivers returns through reduced labor costs, increased efficiency, and improved workplace safety.