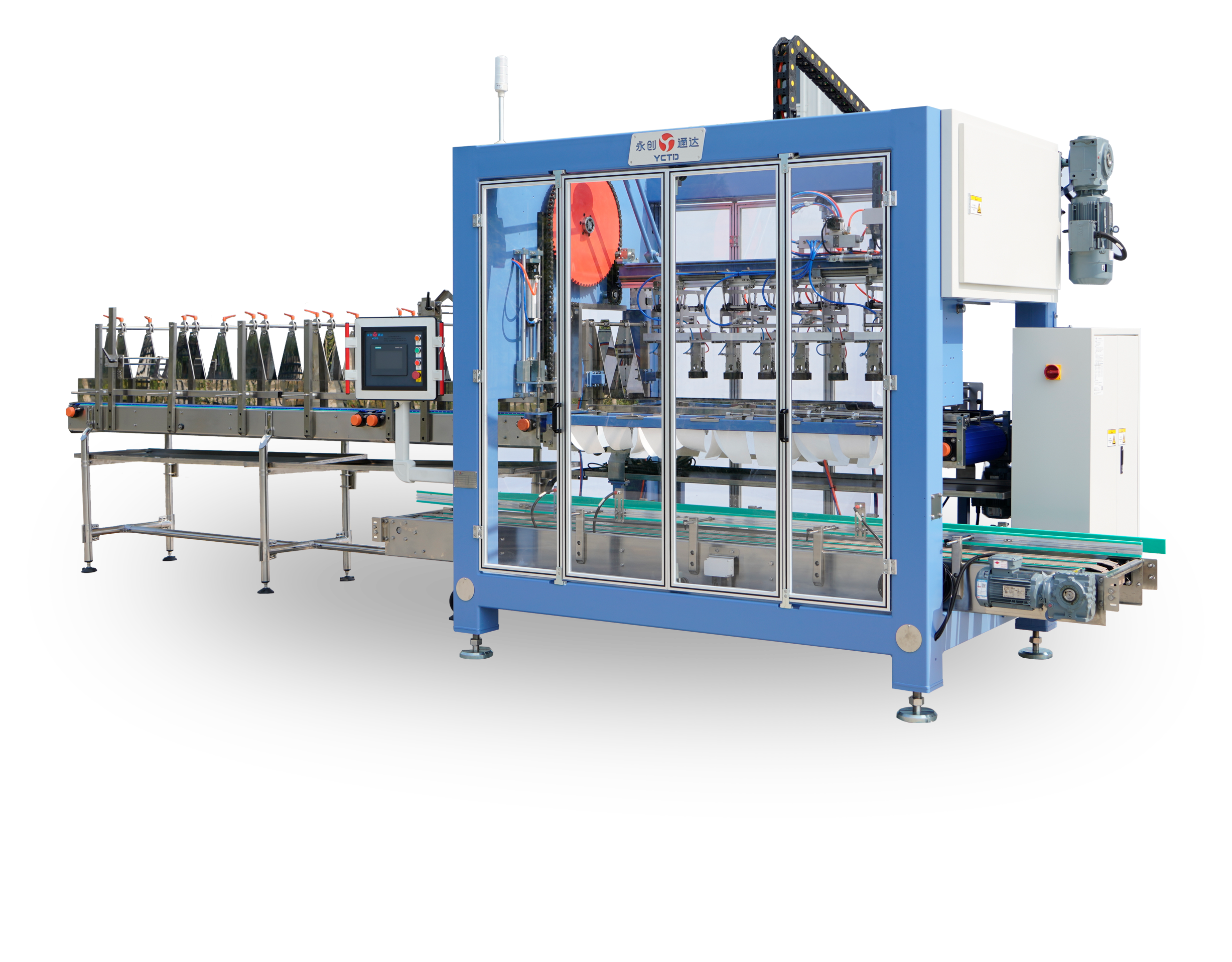

depalletizer machine

A depalletizer machine is an advanced automation solution designed to efficiently unload products or containers from pallets in various industrial settings. This sophisticated equipment combines mechanical precision with smart technology to streamline the depalletizing process, significantly reducing manual labor and increasing operational efficiency. The machine utilizes advanced sensors and programming to detect pallet patterns and product arrangements, enabling seamless layer-by-layer removal of items. Modern depalletizers incorporate multiple safety features, including emergency stops and protective barriers, ensuring worker safety while maintaining high productivity. The machine's versatility allows it to handle different product sizes, shapes, and packaging materials, making it invaluable across diverse industries such as beverage, food processing, pharmaceutical, and consumer goods. Advanced models feature adjustable speed controls, automated pallet stack management, and integrated conveyor systems for smooth product transition. The equipment's robust construction ensures reliable performance under continuous operation, while its precision handling capabilities minimize product damage during the depalletizing process.