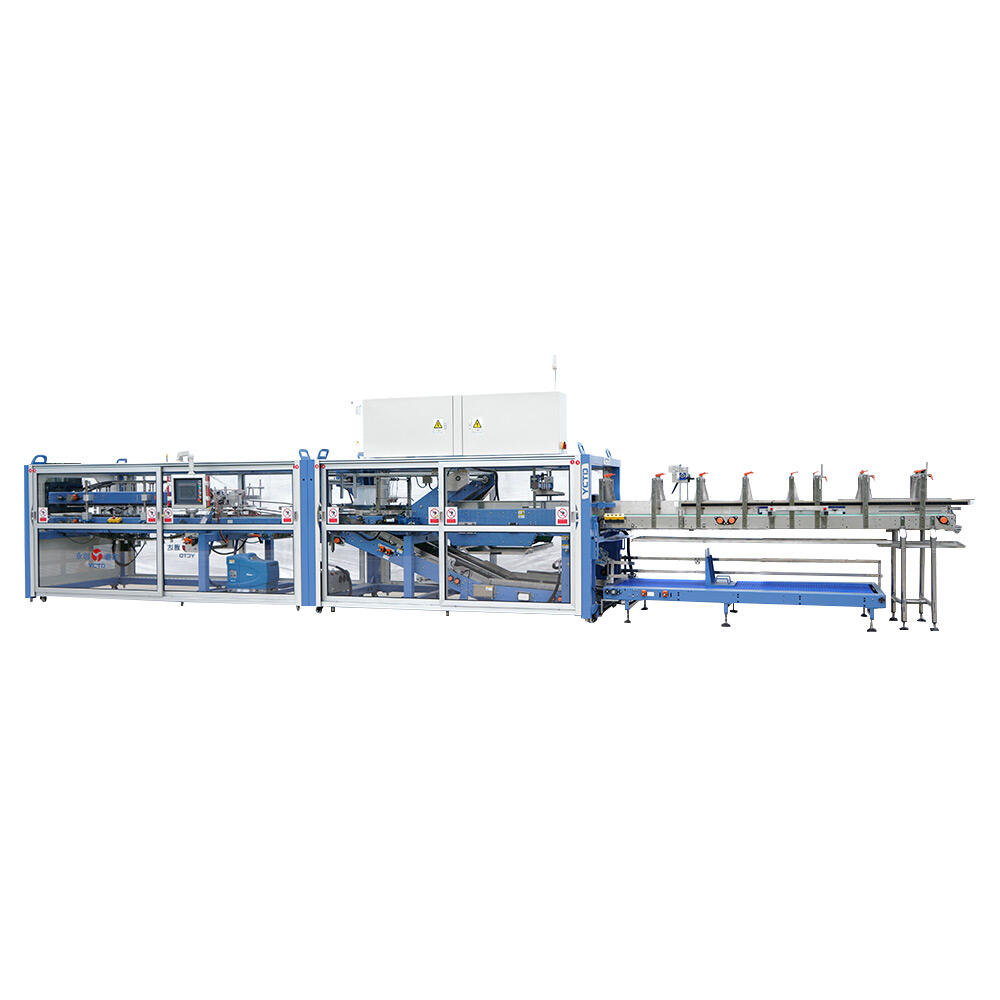

robotic depalletizer

A robotic depalletizer is an advanced automation solution designed to efficiently unload stacked products from pallets in warehouses and distribution centers. This sophisticated system combines precision robotics with intelligent sensing technology to handle various product sizes, shapes, and packaging types. The system utilizes advanced vision systems and sensors to identify product placement and orientation, enabling accurate and consistent depalletizing operations. The robotic arm, equipped with specialized end-of-arm tooling, can handle multiple items simultaneously, significantly increasing throughput compared to manual operations. Modern robotic depalletizers incorporate artificial intelligence and machine learning capabilities to optimize movement patterns and adapt to different pallet configurations. These systems can operate continuously in various environments, maintaining consistent performance levels regardless of temperature, humidity, or lighting conditions. The technology includes safety features such as collision detection and emergency stop functions, ensuring worker safety while maximizing operational efficiency. Integration capabilities with warehouse management systems allow for real-time tracking and automated inventory management, making it an essential component in modern logistics operations.