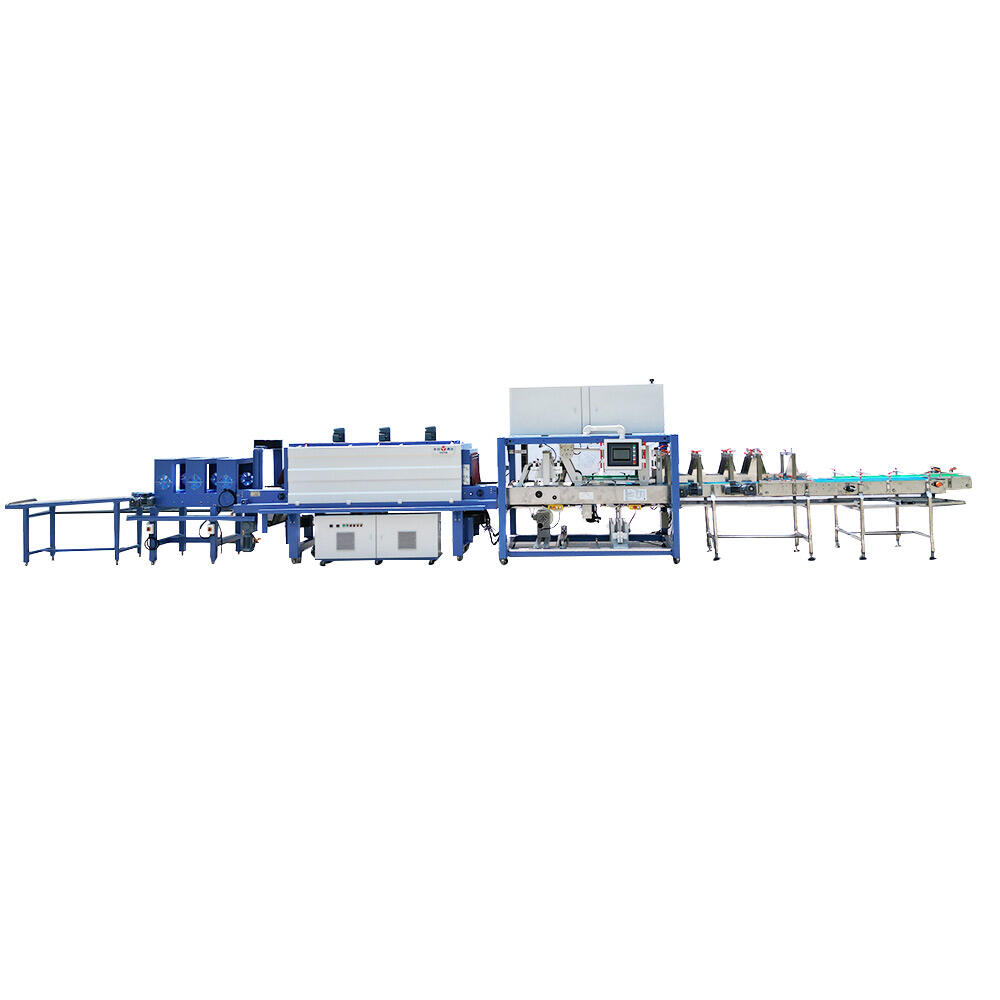

industrial shrink wrap machine

The industrial shrink wrap machine represents a cornerstone of modern packaging automation, designed to efficiently secure and protect products of varying sizes and shapes. This sophisticated equipment utilizes heat-shrinking technology to create tight, professional packaging that enhances product presentation and protection. The machine operates by enveloping items in specialized shrink film and passing them through a heated chamber, where controlled temperature causes the film to contract uniformly around the product. Advanced models feature adjustable temperature controls, variable speed conveyor systems, and precise sealing mechanisms that ensure consistent results. These machines can accommodate both individual items and bundled products, making them versatile enough for diverse manufacturing environments. The technology incorporates safety features such as emergency stops, cool-down cycles, and thermal protection systems to ensure operator safety and equipment longevity. Modern industrial shrink wrap machines often include digital controls for precise operation parameters, energy-efficient heating systems, and automated feed mechanisms that streamline the packaging process. They're capable of handling continuous operation in high-volume production environments while maintaining consistent packaging quality.