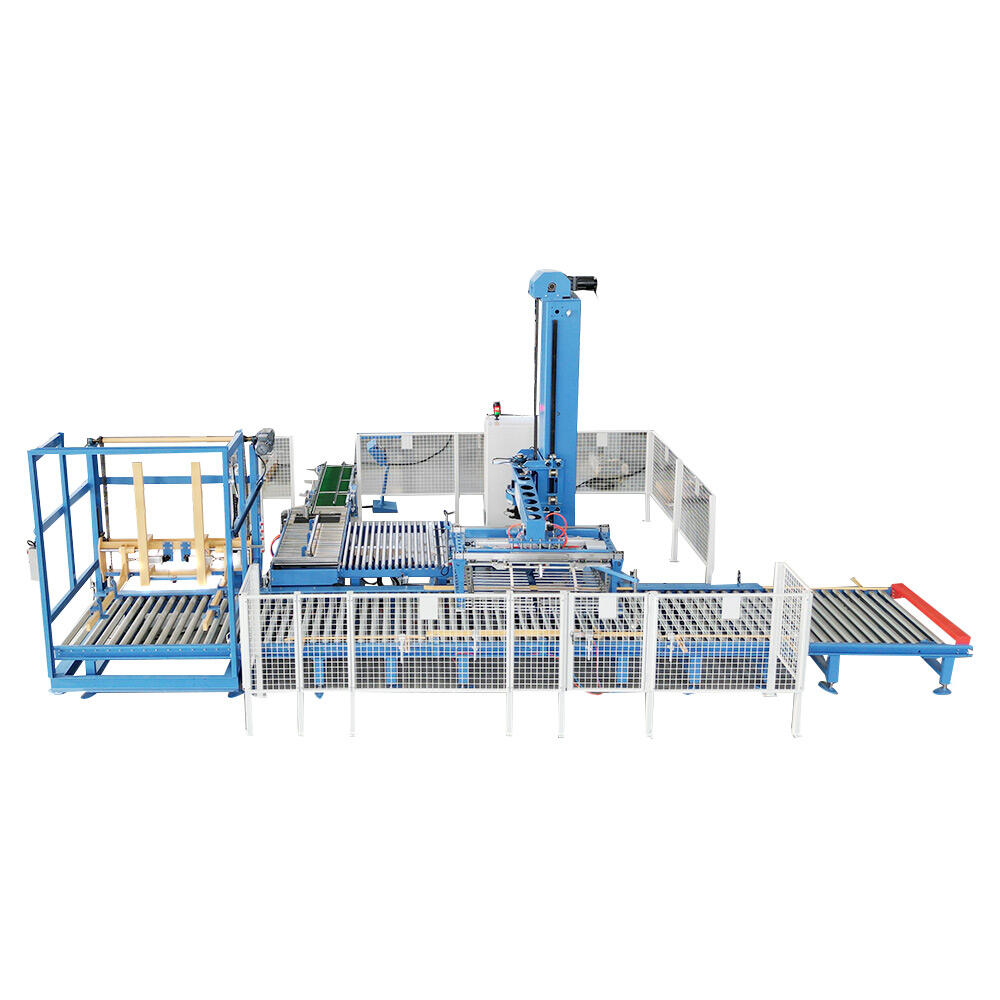

semi automatic palletizer

A semi automatic palletizer represents a crucial advancement in material handling technology, combining human oversight with automated efficiency. This innovative system streamlines the palletizing process by mechanically stacking products onto pallets while requiring minimal operator intervention. The machine typically consists of a product infeed system, lifting mechanism, and pallet positioning platform. It efficiently handles various product types, from boxes and bags to drums and crates, with adjustable settings to accommodate different sizes and weights. The system's programming allows for multiple stacking patterns and layer configurations, ensuring optimal load stability and space utilization. Operating at speeds of up to 15 layers per minute, these machines significantly reduce physical strain on workers while maintaining precise product placement. Advanced safety features include emergency stop buttons, light curtains, and protective barriers, ensuring operator safety during operation. The control interface typically features a user-friendly touchscreen display that allows for easy pattern selection and operational adjustments. These systems can be integrated with existing production lines and often include conveyor systems for smooth product flow. The semi automatic nature of these machines provides an ideal balance between automation and human control, making them particularly suitable for medium-sized operations seeking to optimize their palletizing processes while maintaining flexibility and cost-effectiveness.