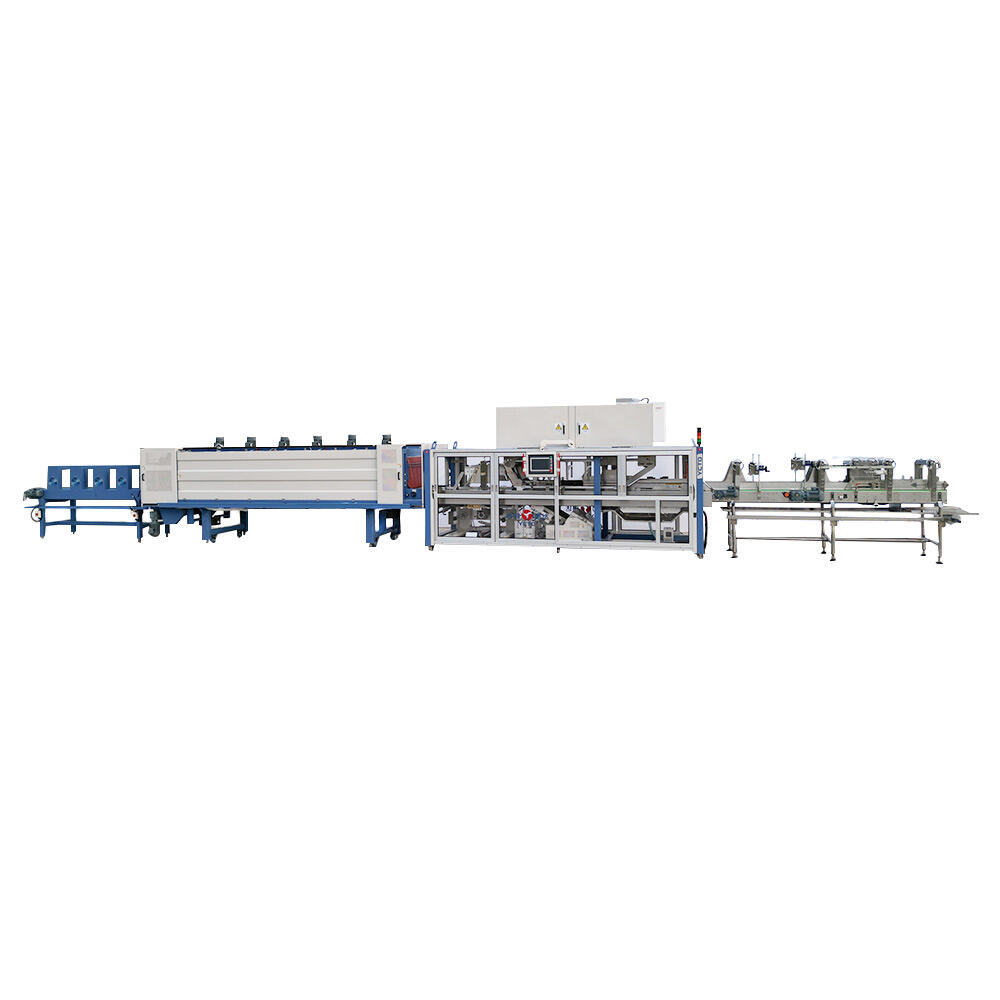

shrink wrap machine for food packaging

A shrink wrap machine for food packaging represents a vital piece of equipment in modern food processing and packaging operations. This sophisticated machinery utilizes heat-shrinkable film to create secure, tamper-evident packaging that preserves food freshness and extends shelf life. The machine operates by wrapping items in specialized plastic film and applying controlled heat, causing the material to shrink tightly around the product. Advanced models feature precise temperature controls, adjustable sealing mechanisms, and variable speed settings to accommodate different product sizes and packaging requirements. The technology incorporates automated feeding systems, conveyor belts, and shrink tunnels that ensure consistent, high-quality packaging results. These machines can handle various food products, from fresh produce and meats to prepared meals and bakery items, making them versatile additions to any food packaging operation. The process typically involves product loading, film wrapping, sealing, and heat shrinking phases, all carefully coordinated to maintain product integrity and appearance. Modern shrink wrap machines are designed with user-friendly interfaces, safety features, and energy-efficient components, meeting current industry standards for food packaging equipment.