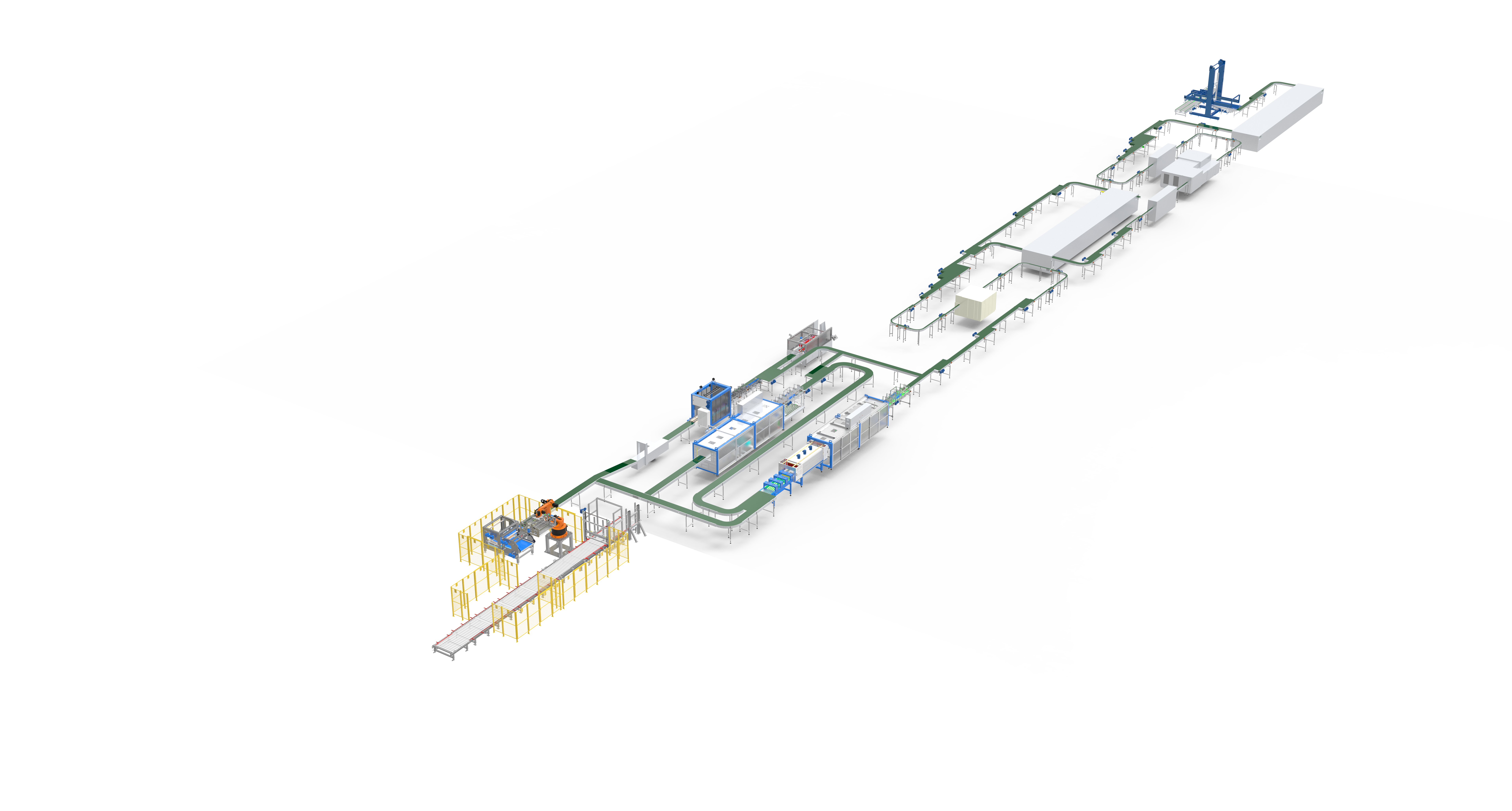

beverage line cleaner

The beverage line cleaner represents a cutting-edge solution for maintaining hygiene and efficiency in beverage production facilities. This advanced cleaning system utilizes innovative technology to ensure thorough sanitization of beverage lines, tanks, and associated equipment. The system employs a combination of high-pressure washing, chemical circulation, and temperature control mechanisms to eliminate bacterial growth, remove mineral deposits, and prevent product contamination. Designed for both automated and manual operation, the cleaner features programmable cleaning cycles that can be customized according to specific production requirements. The unit incorporates smart sensors that monitor cleaning parameters such as temperature, chemical concentration, and flow rates in real-time, ensuring optimal cleaning performance. Its versatile design allows for compatibility with various beverage production systems, including carbonated drinks, juices, dairy products, and alcoholic beverages. The cleaner's efficient water and chemical usage helps reduce operational costs while maintaining superior cleaning results. Additionally, the system includes advanced safety features such as emergency shut-off mechanisms and chemical containment systems to protect operators and equipment.