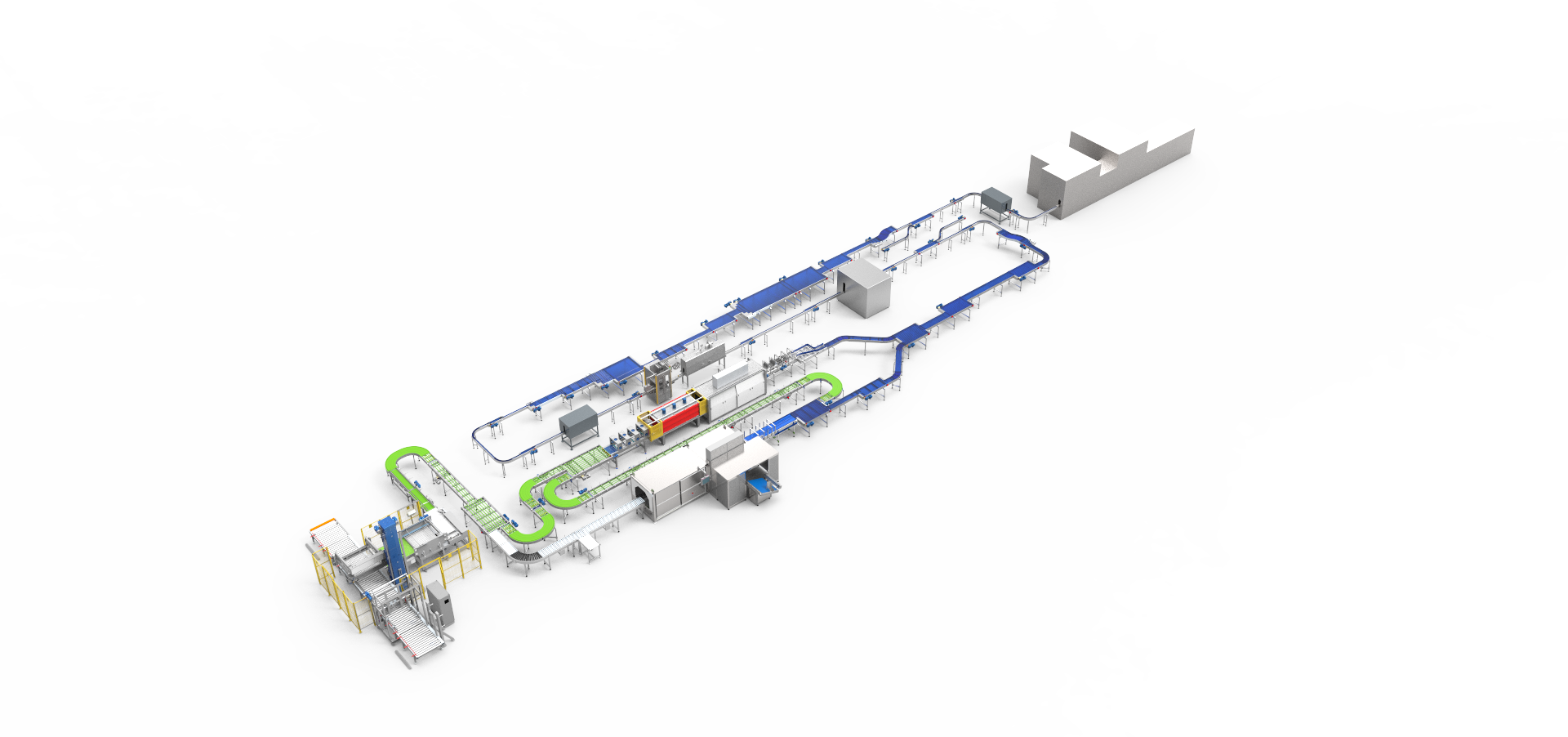

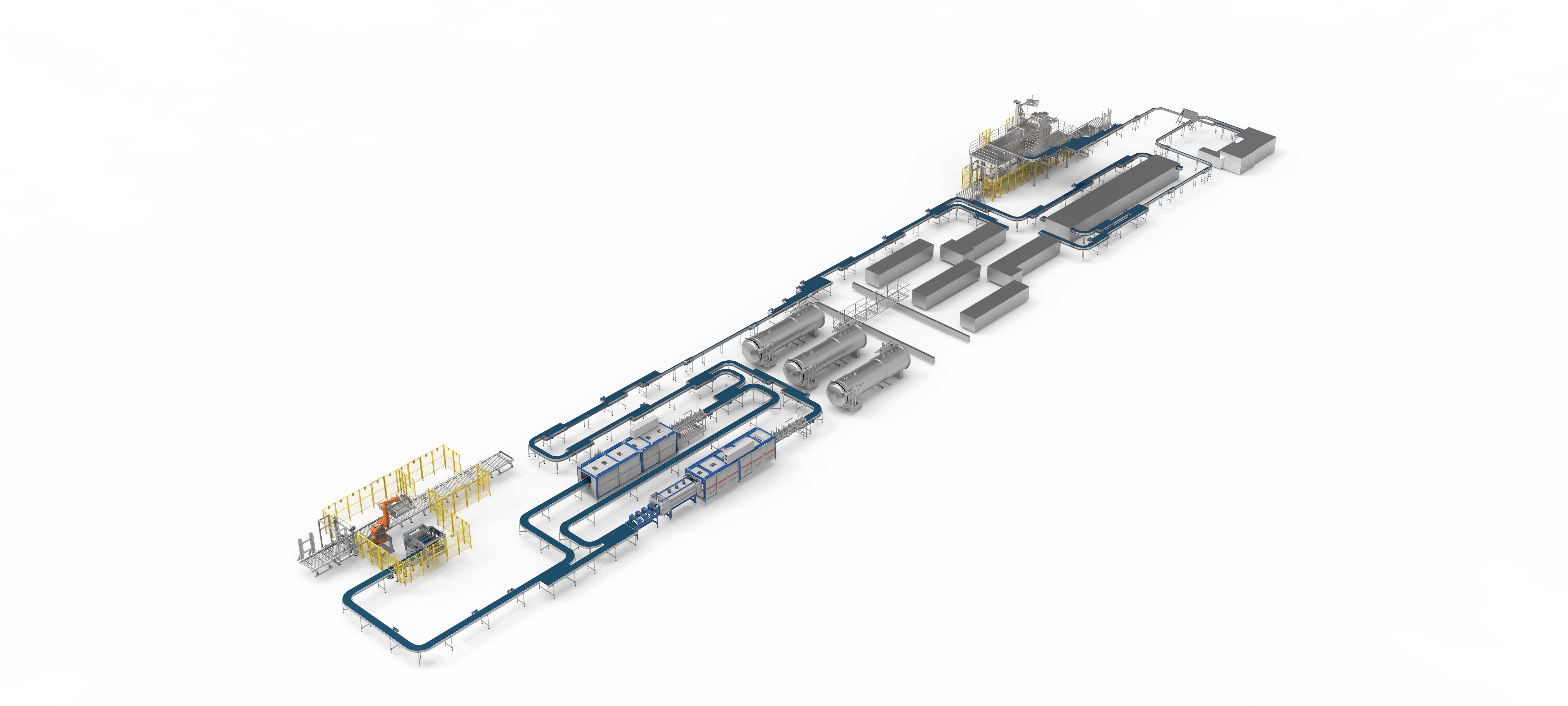

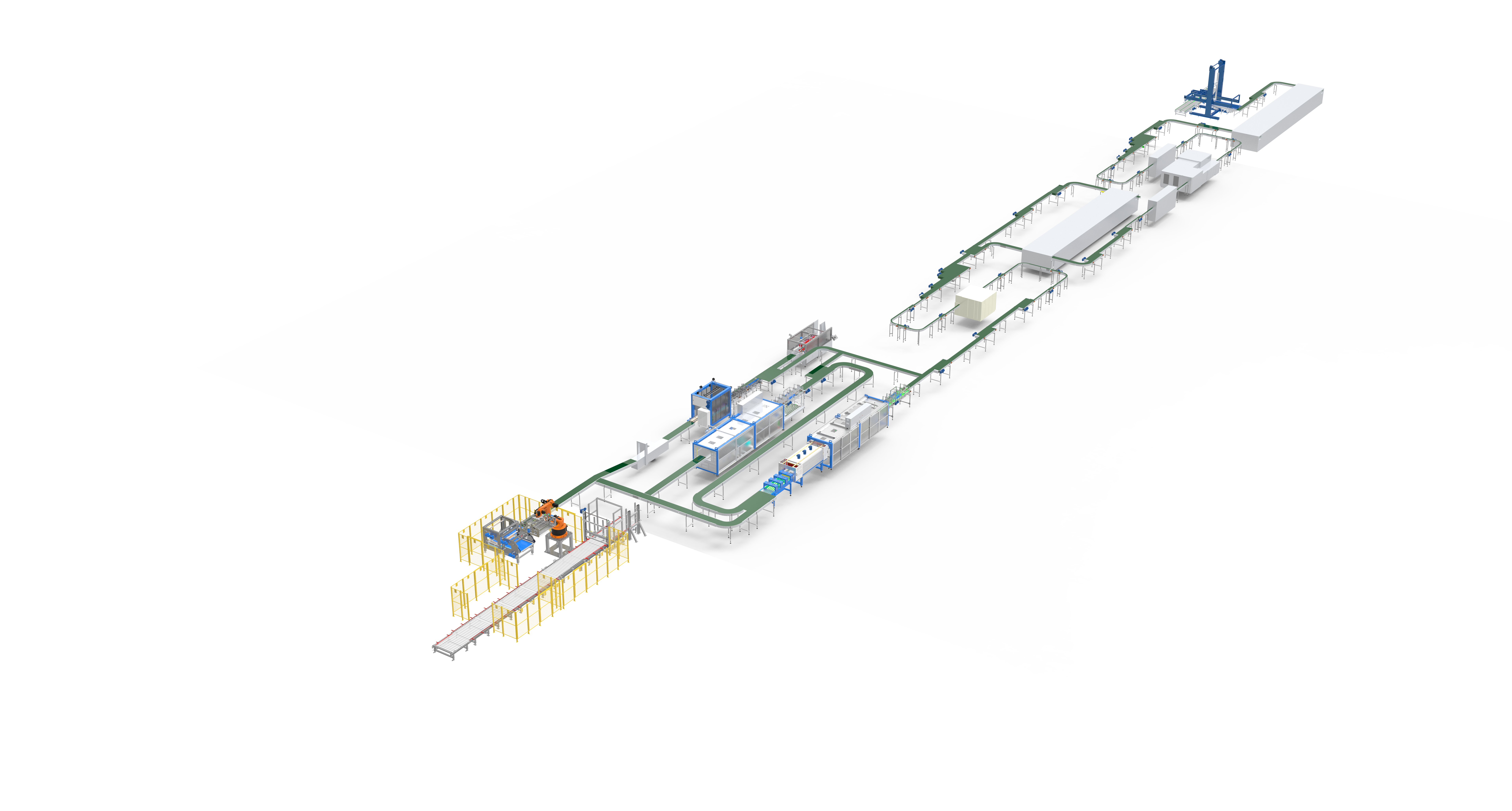

juice beverage processing line

A juice beverage processing line represents a comprehensive solution for efficiently transforming raw fruits and vegetables into marketable juice products. This advanced system incorporates multiple integrated stations that handle everything from initial fruit washing and sorting to the final packaging of the finished beverage. The line begins with a receiving station where raw materials undergo thorough cleaning and inspection, followed by a crushing or pressing station that efficiently extracts juice from the produce. Advanced filtration systems remove unwanted particles and pulp, ensuring consistent product quality. The processing line features precision-controlled pasteurization units that eliminate harmful microorganisms while preserving essential nutrients and flavors. State-of-the-art homogenization equipment ensures uniform product consistency, while sophisticated mixing systems allow for precise blending of ingredients, additives, and preservatives. The line culminates in automated filling and packaging stations that maintain product sterility and extend shelf life. Modern juice processing lines are equipped with digital control systems that monitor and adjust processing parameters in real-time, ensuring optimal production efficiency and product quality. These systems are designed to handle various capacities, from small-batch processing to industrial-scale production, making them suitable for both emerging businesses and established manufacturers.