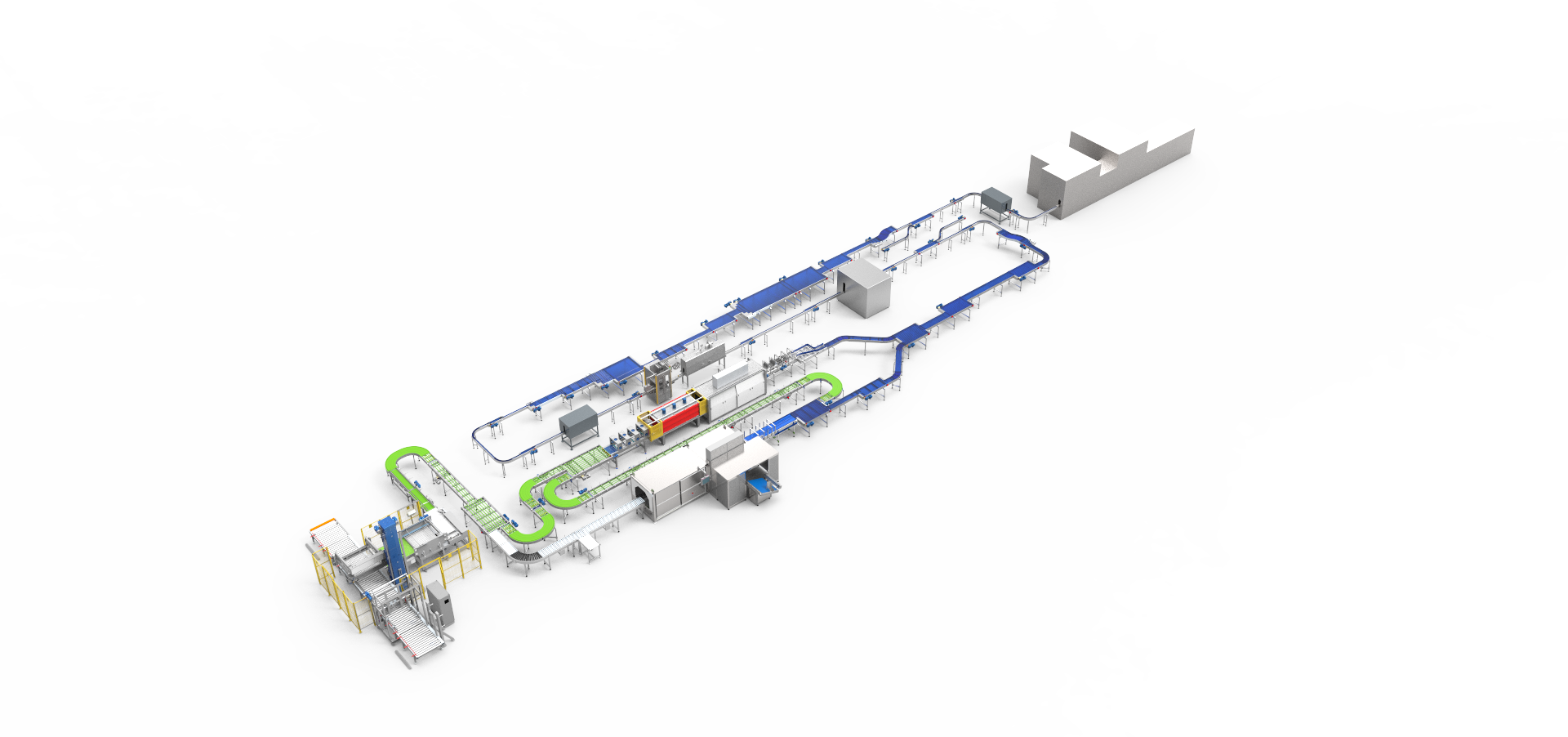

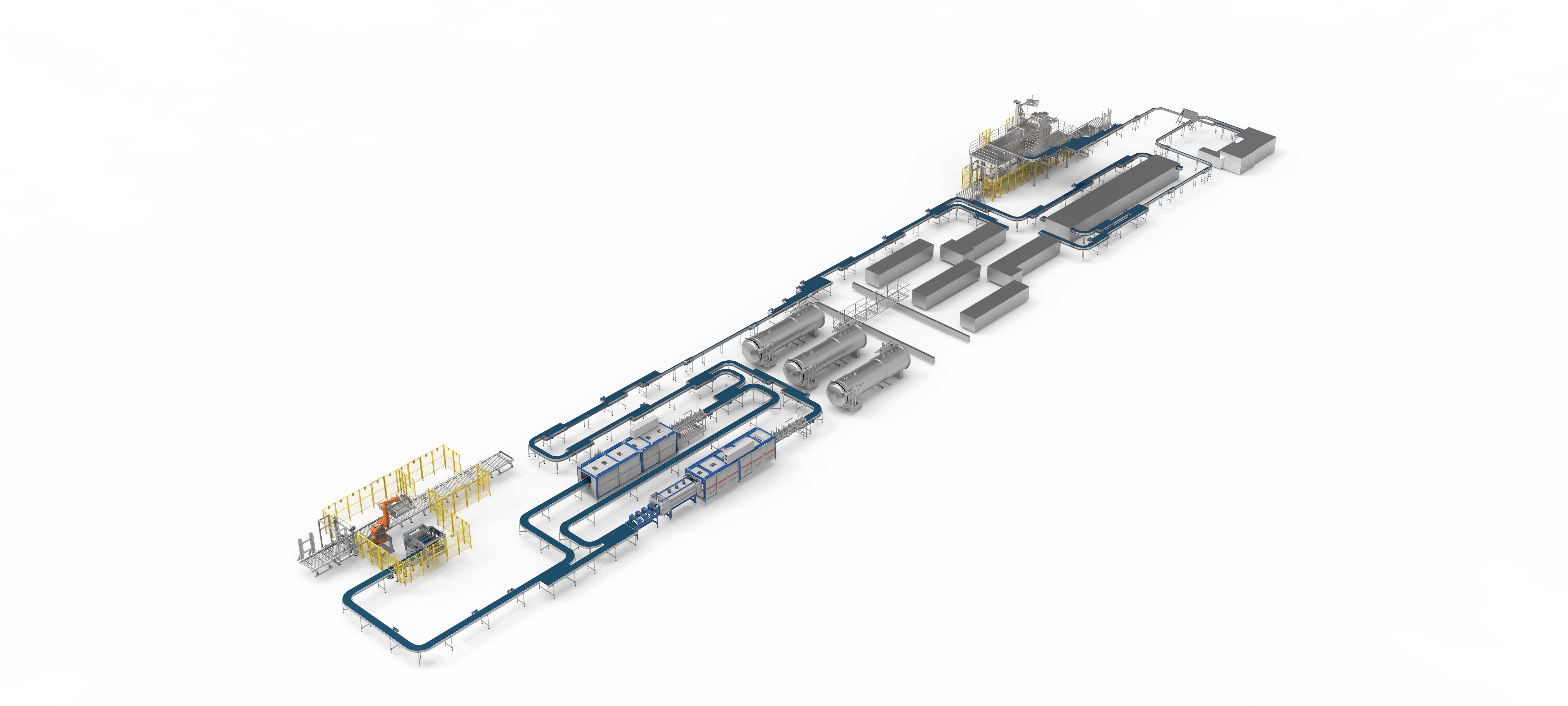

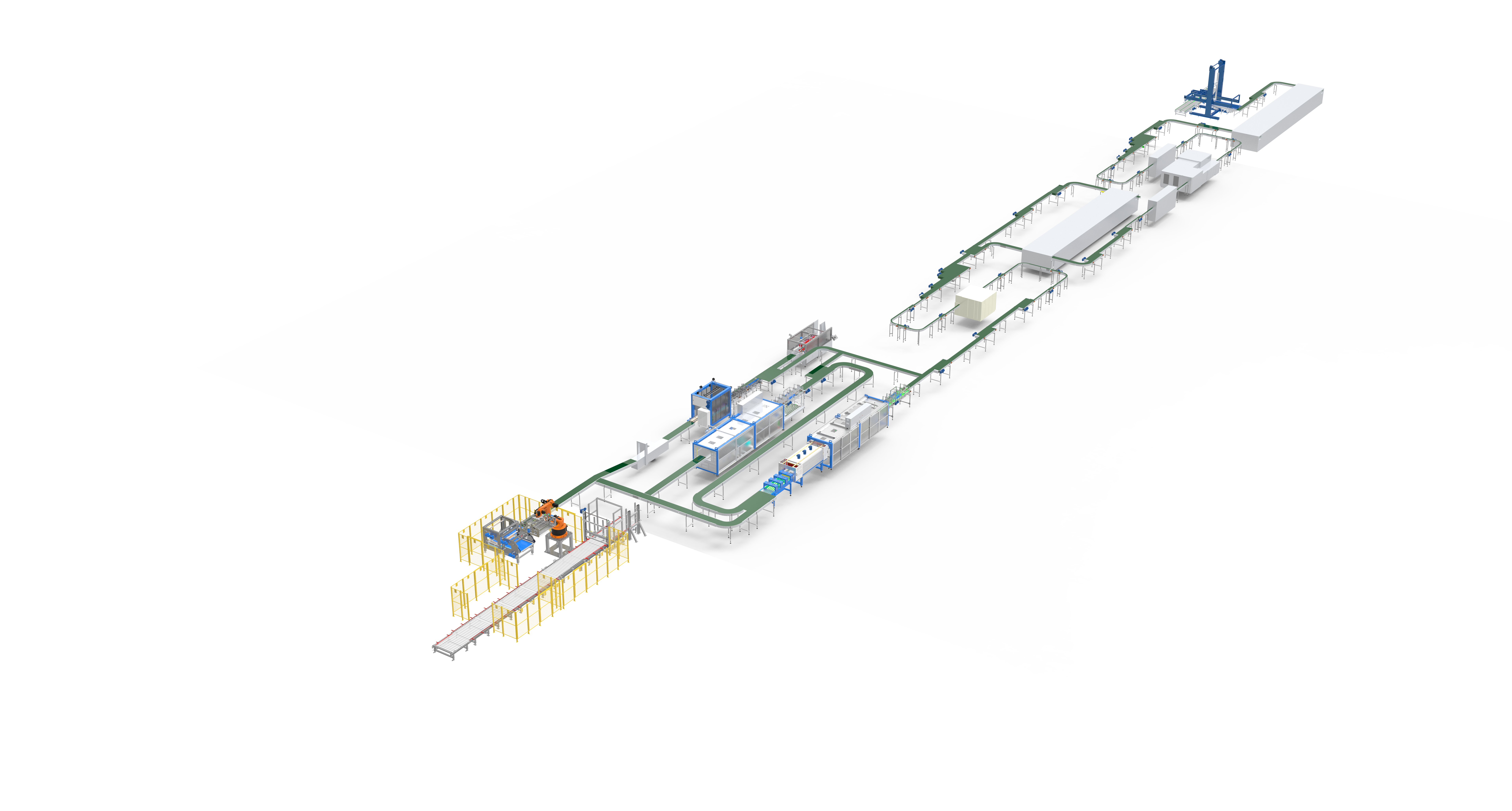

automatic beverage filling line

The automatic beverage filling line represents a state of the art solution in modern beverage production, integrating multiple processes into a seamless operation. This sophisticated system handles everything from bottle rinsing to filling and capping, ensuring consistent quality and maximum efficiency. The line typically begins with an automatic bottle unscrambler, feeding containers into a precision rinser that removes potential contaminants. The core filling station utilizes advanced volumetric technology, guaranteeing accurate fill levels across various beverage types, from carbonated drinks to still water. Integration of real time monitoring systems enables operators to track production parameters, including fill levels, pressure, and temperature. The line incorporates multiple quality control checkpoints, utilizing sensors and vision systems to detect defects or irregularities. With production speeds ranging from 1,000 to 50,000 bottles per hour, these systems can be customized to meet specific capacity requirements. The filling line also features CIP (Clean in Place) systems, ensuring thorough sanitization between production runs. Modern lines are equipped with user friendly HMI interfaces, allowing for easy operation and quick format changes. This automated solution significantly reduces labor costs while maintaining consistent product quality across extended production runs.