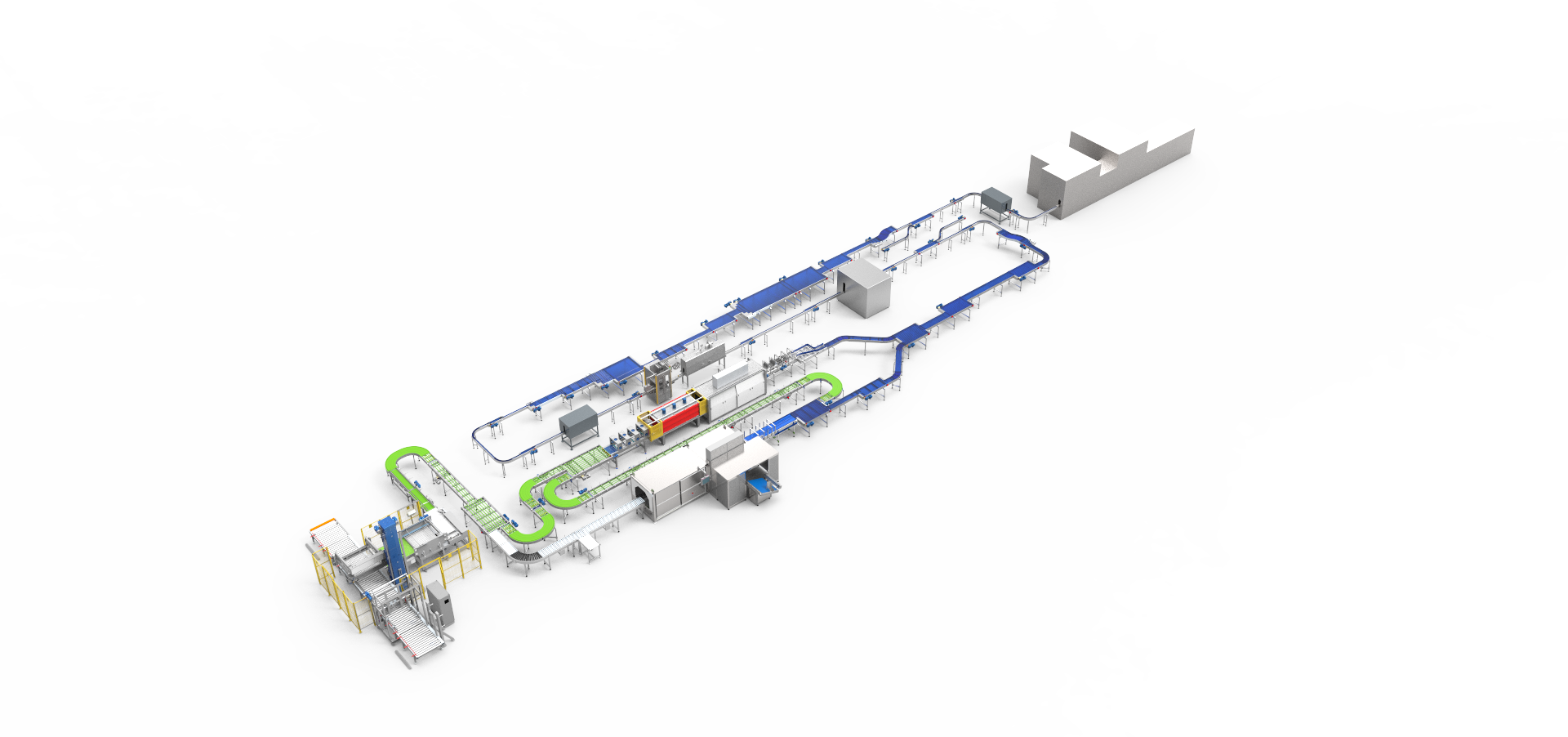

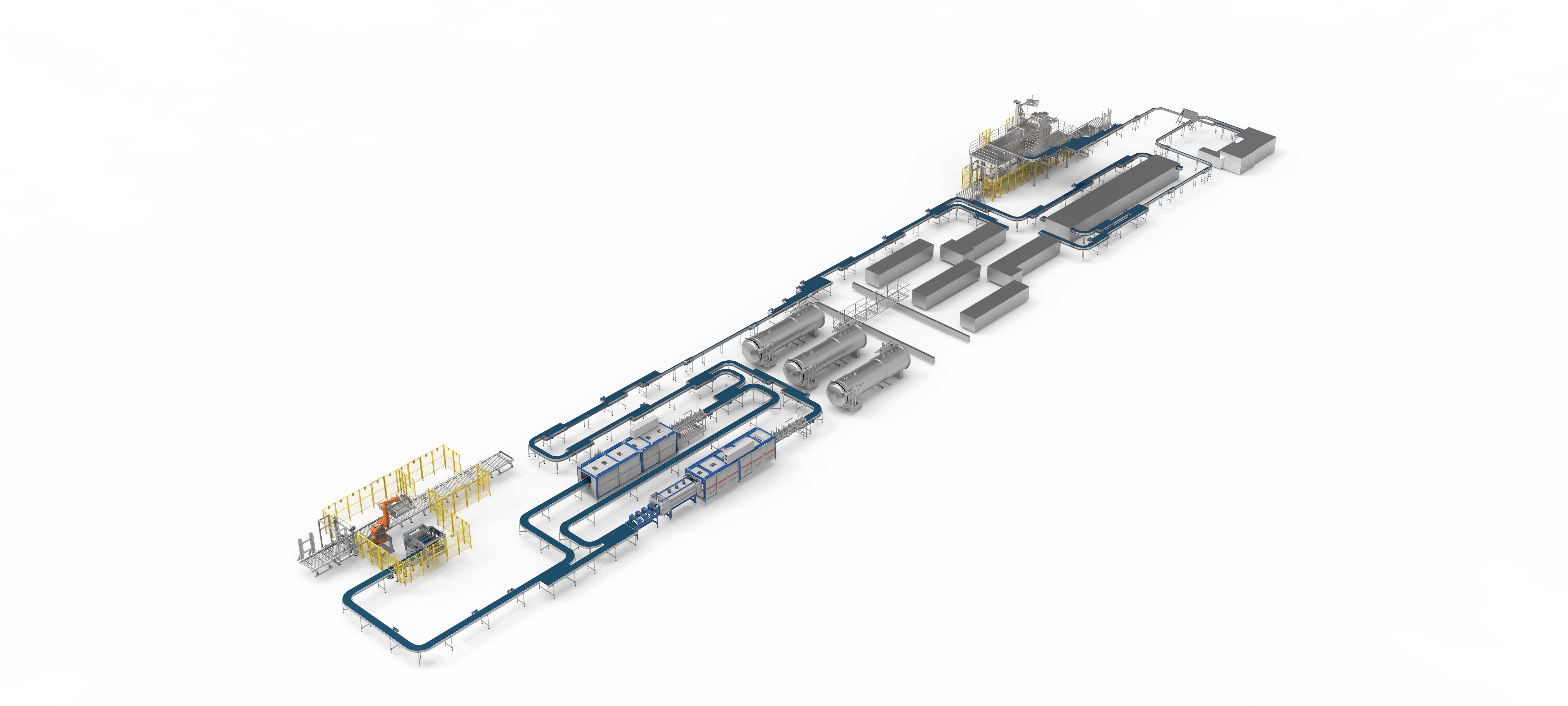

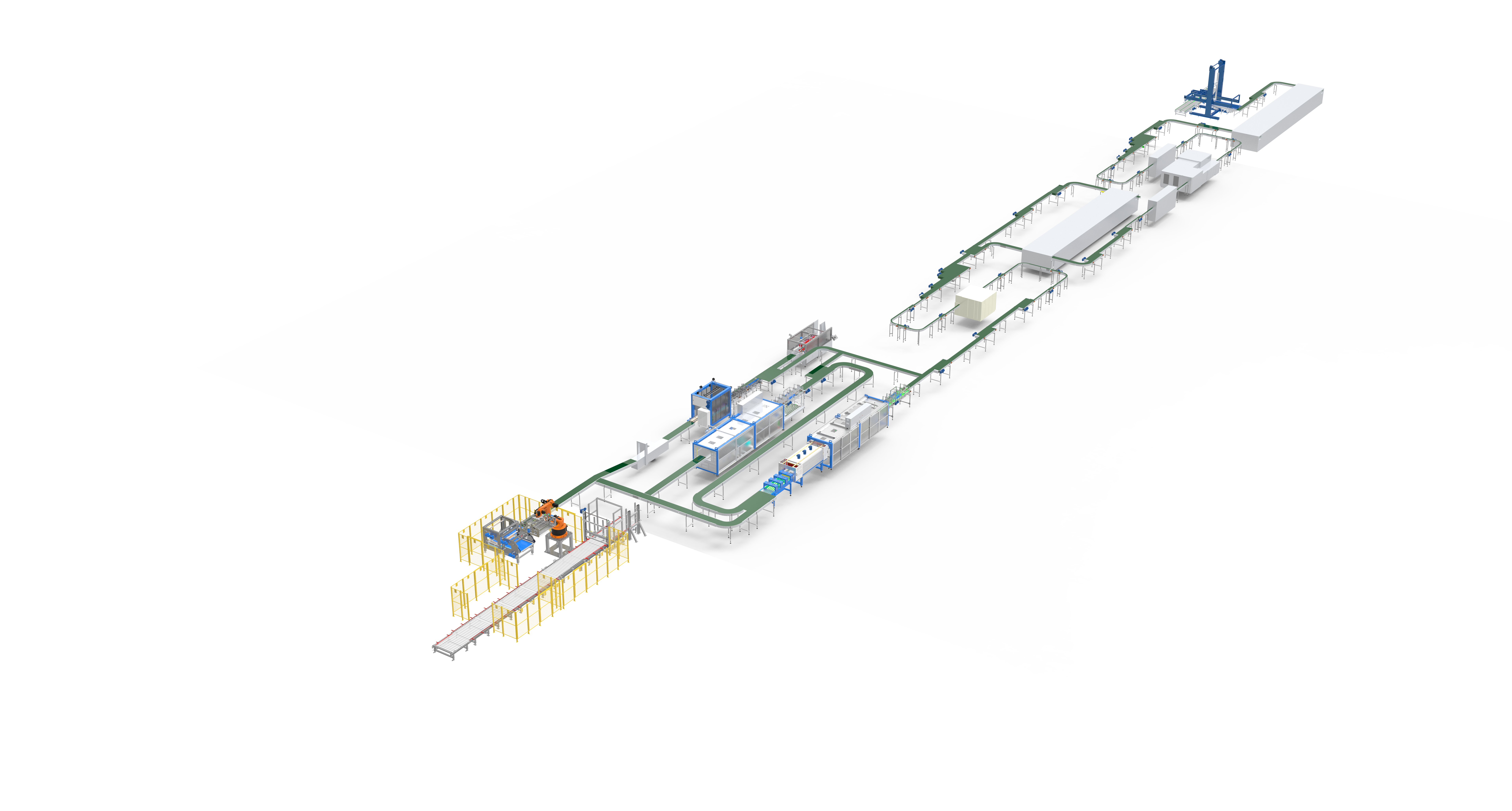

beverage packaging line

A beverage packaging line represents a sophisticated automated system designed to efficiently process, fill, and package various types of beverages. This comprehensive solution integrates multiple stages of production, from bottle preparation to final packaging. The line typically begins with a depalletizer that systematically arranges containers for processing, followed by a rinser that ensures optimal hygiene standards. The core components include precision filling stations equipped with advanced volumetric technology, ensuring accurate dispensing of beverages while maintaining product integrity. Modern beverage packaging lines incorporate high-speed capping systems that can handle various closure types, from traditional screw caps to sports caps. Quality control stations featuring vision systems and check weighers monitor product consistency throughout the process. The line also includes labeling machines capable of applying different label types with precise positioning. End-of-line equipment such as case packers, shrink wrappers, and palletizers complete the packaging process. These systems are controlled by sophisticated PLC systems that enable real-time monitoring and adjustments, ensuring optimal performance and minimizing downtime. The line's modular design allows for easy maintenance and future upgrades, making it a sustainable long-term investment for beverage manufacturers.