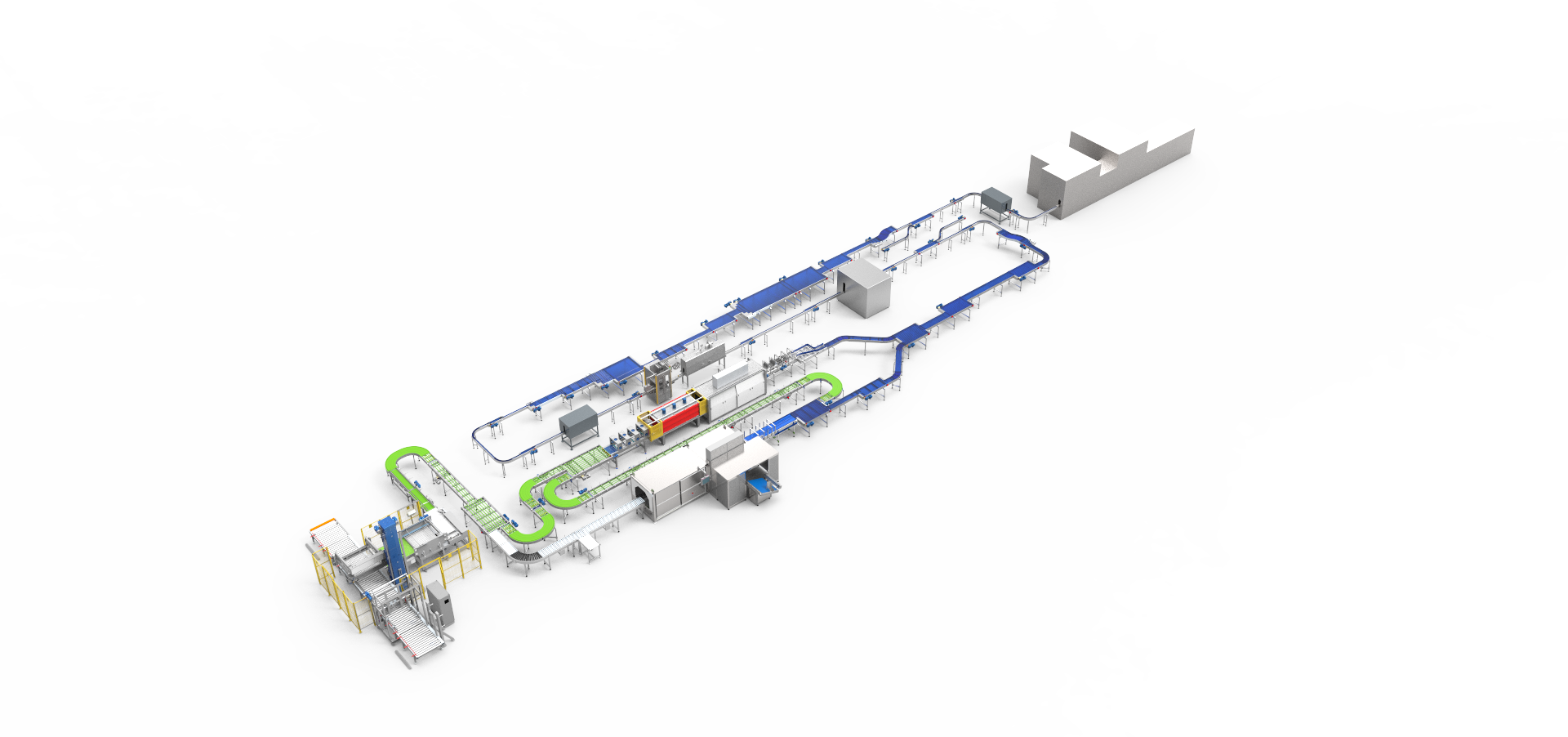

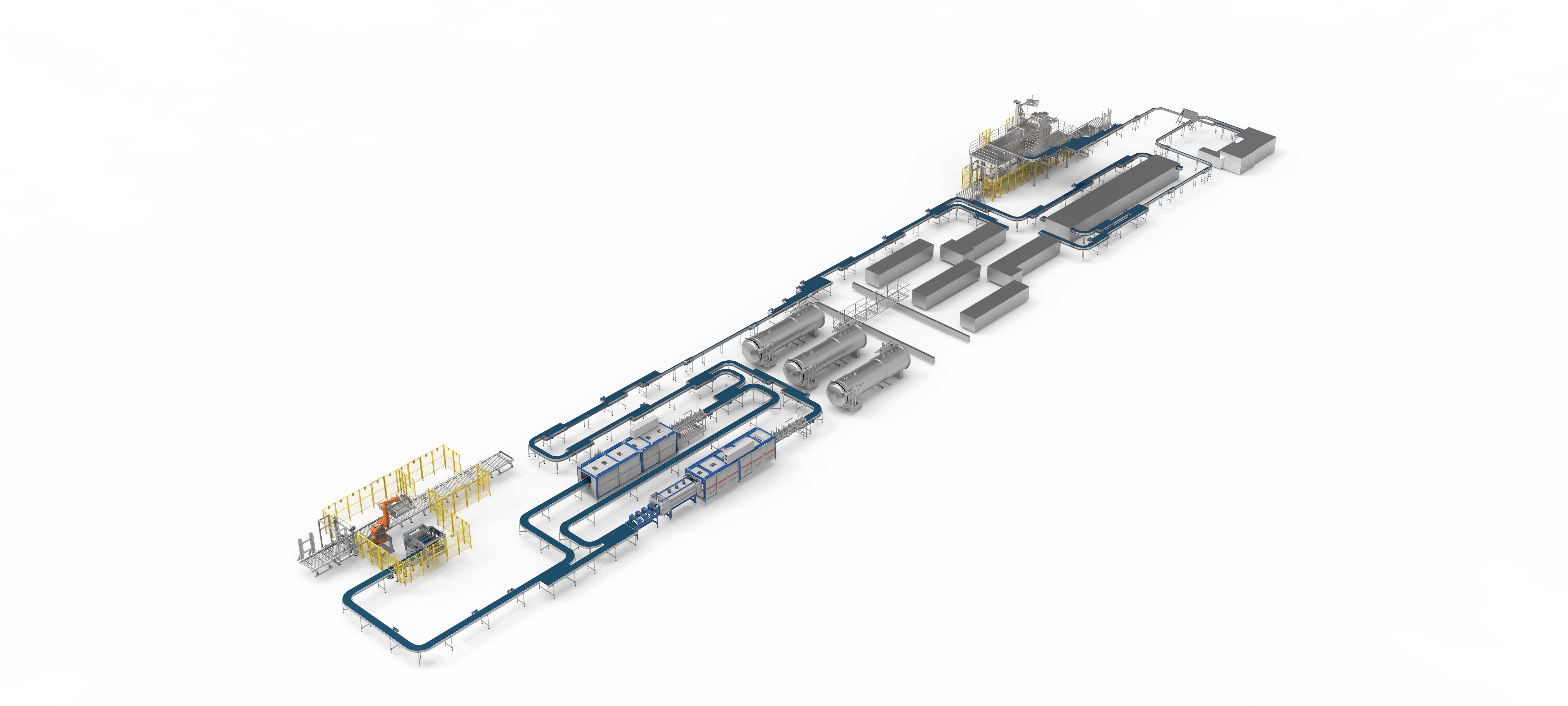

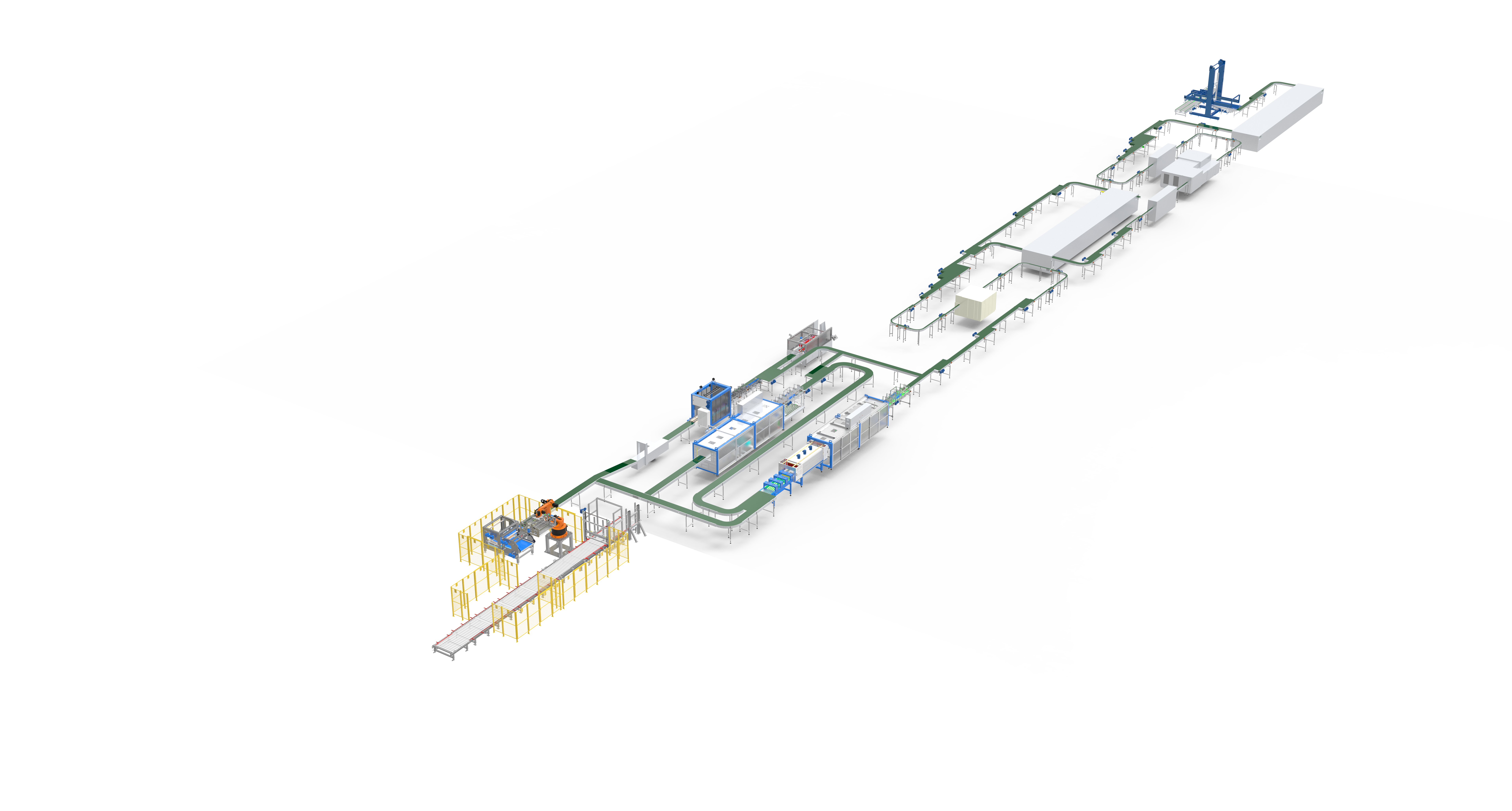

beverage canning line

A beverage canning line represents a sophisticated automated system designed to efficiently package beverages in aluminum or steel cans. This integrated production line encompasses multiple stations that work seamlessly together, starting from can handling and preparation through filling, seaming, and final packaging. The line begins with depalletizing and rinsing stations, where cans are systematically arranged and cleaned. Advanced filling stations utilize precise volumetric or flow meter technologies to ensure accurate product dispensing, while maintaining product integrity and preventing contamination. The seaming station employs high-precision mechanics to create airtight double seams, crucial for product preservation and shelf life. Modern beverage canning lines incorporate cutting-edge inspection systems that monitor fill levels, seal integrity, and overall can quality. These systems typically operate at speeds ranging from 100 to 1000 cans per minute, depending on the model and configuration. The line concludes with coding, labeling, and packaging stations, where finished products are prepared for distribution. Throughout the process, automated controls and sensors maintain optimal operating parameters, ensuring consistent product quality and minimizing waste.