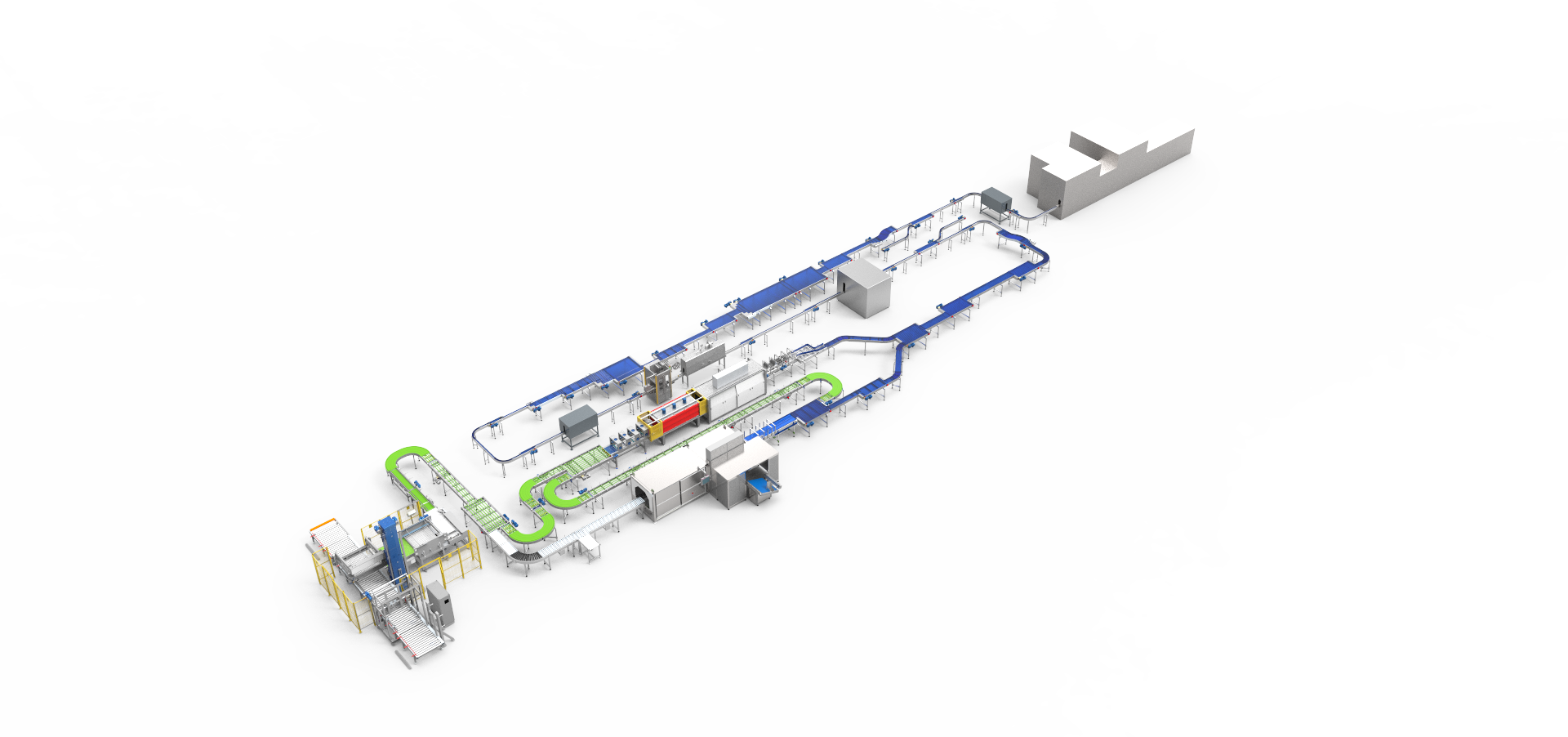

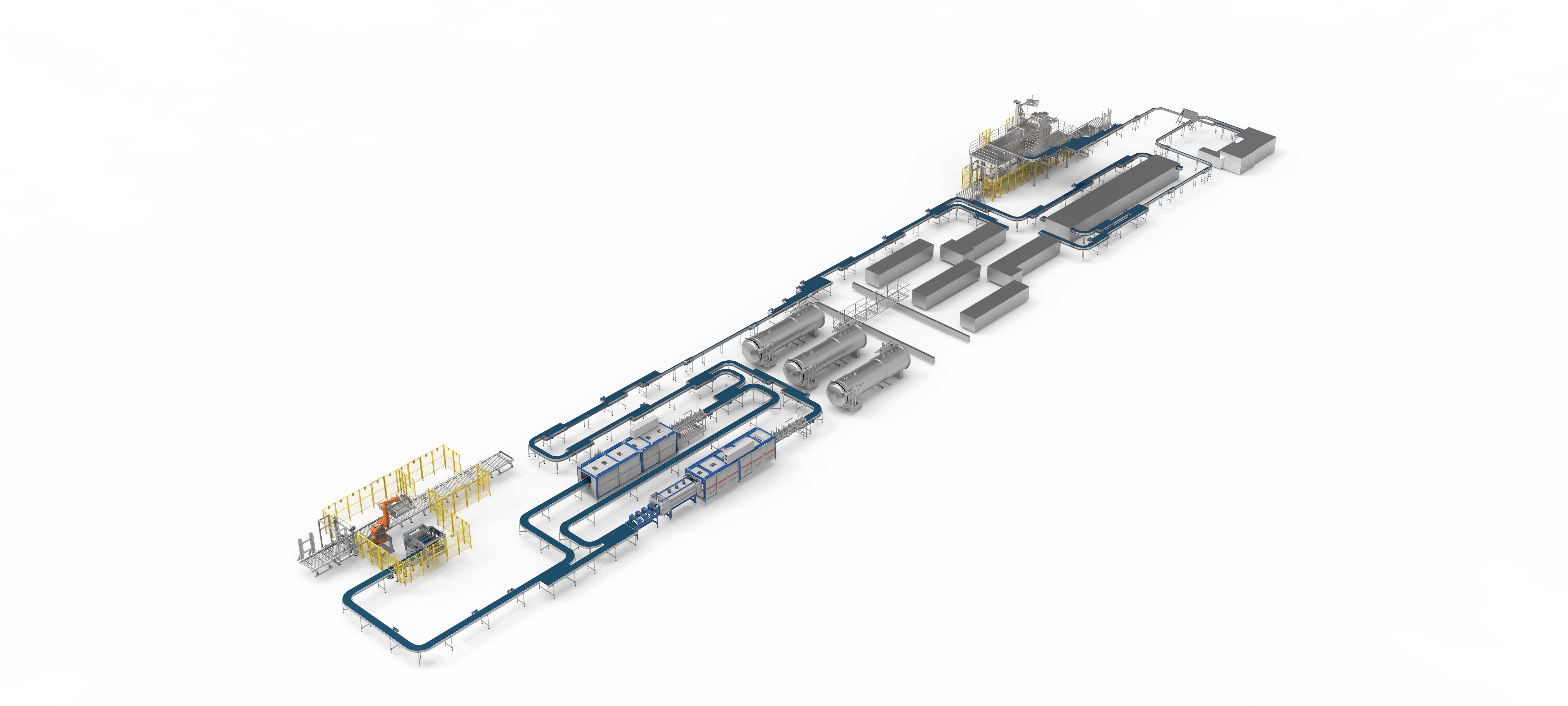

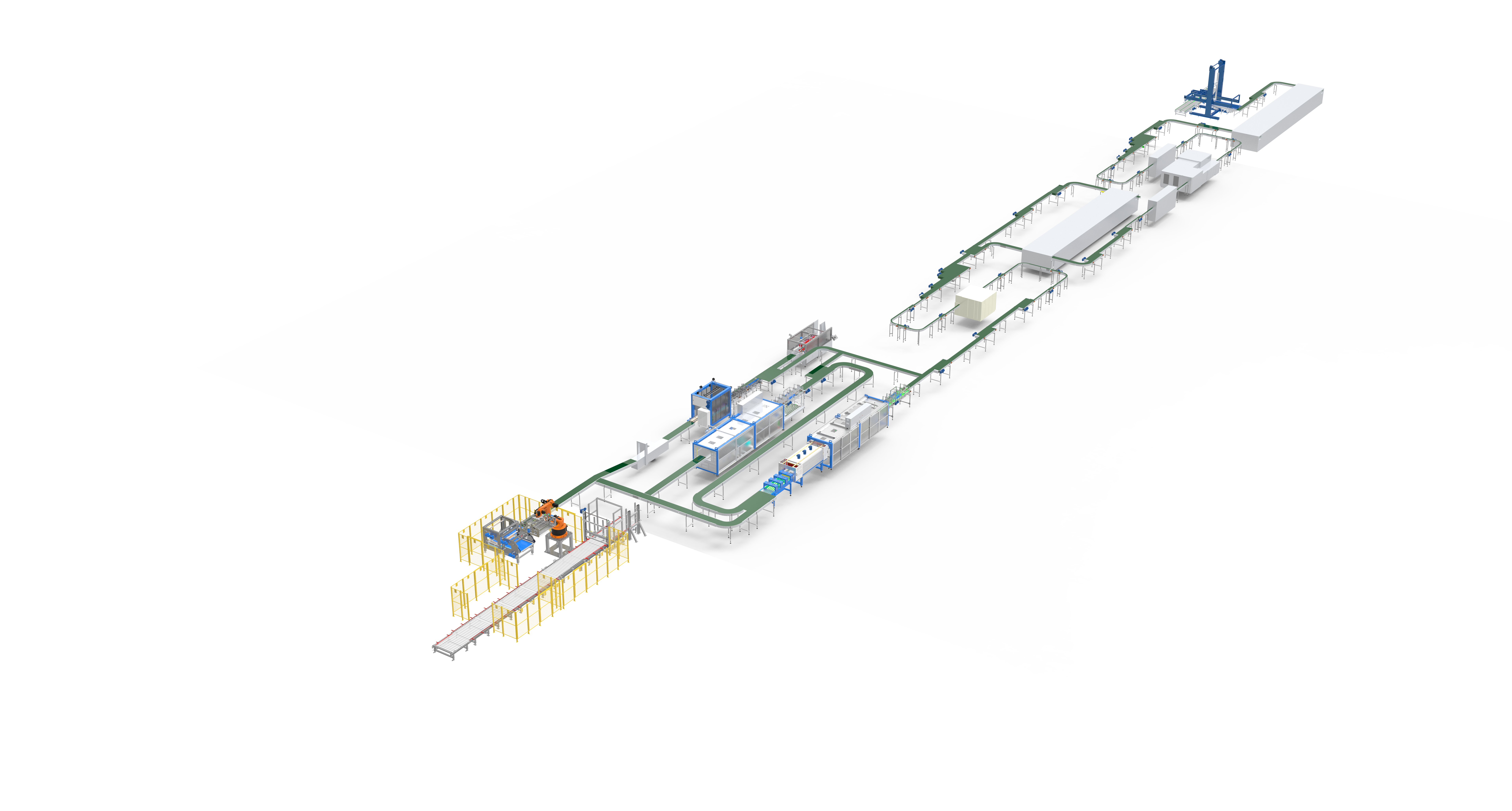

beverage line

The advanced beverage production line represents a comprehensive solution for modern drink manufacturing, integrating cutting-edge automation technology with precision engineering. This state-of-the-art system handles everything from initial ingredient processing to final packaging, ensuring consistent quality and maximum efficiency. The line features sophisticated filling systems capable of handling various container sizes and types, while maintaining strict hygiene standards through CIP (Clean-in-Place) technology. Advanced control systems monitor and adjust parameters in real-time, including temperature, pressure, and flow rates, guaranteeing product consistency. The production line incorporates multiple quality control checkpoints, utilizing vision systems and sensors to detect any deviations from established standards. With processing capabilities ranging from carbonated beverages to still drinks, the system demonstrates remarkable versatility in handling different product formulations. The line's modular design allows for easy maintenance and future upgrades, while its energy-efficient components help reduce operational costs. Safety features are integrated throughout, protecting both operators and product integrity. The system's digital interface provides comprehensive production data and analytics, enabling informed decision-making and process optimization.