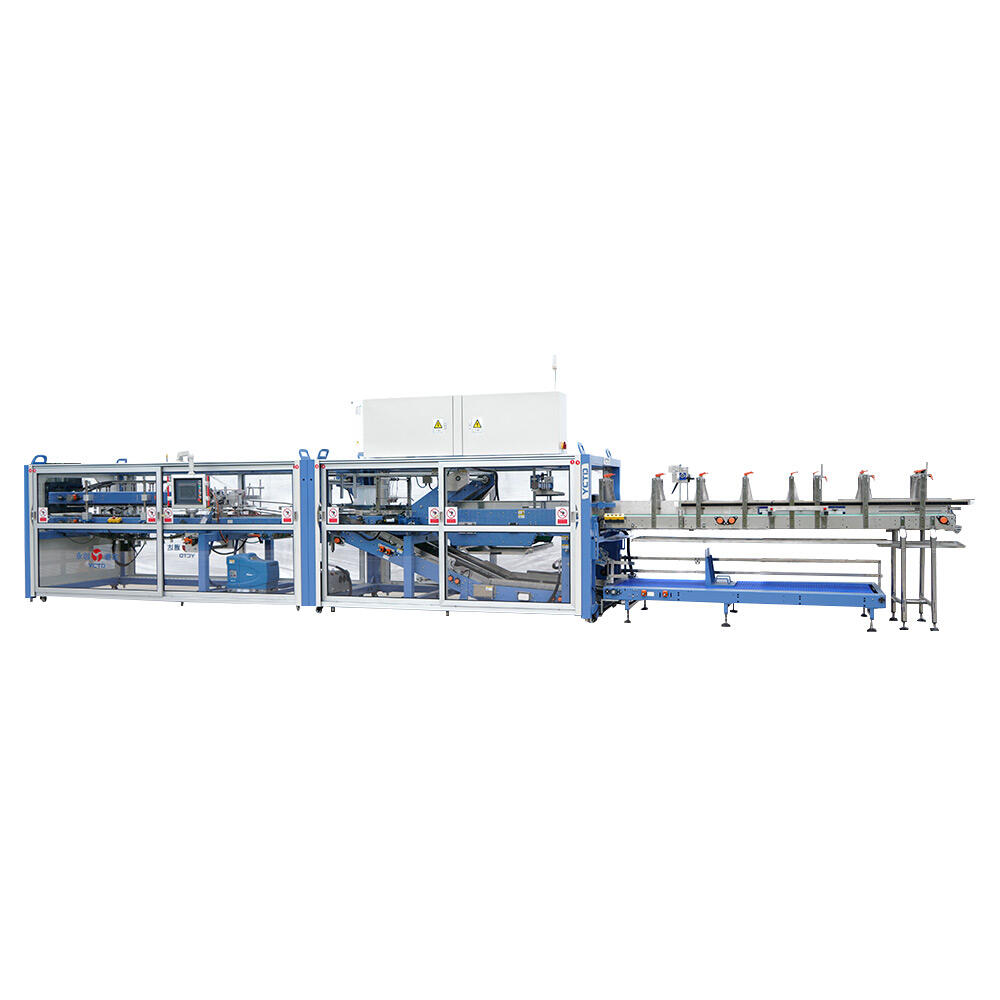

small footprint case packer

The small footprint case packer represents a revolutionary advancement in packaging automation, designed specifically for facilities where space optimization is crucial. This compact yet powerful machine efficiently handles various packaging tasks while occupying minimal floor space. The system integrates seamlessly with existing production lines, capable of processing up to 30 cases per minute depending on the product specifications. It features an intuitive touch screen interface for easy operation and quick changeovers, allowing operators to switch between different case sizes and configurations with minimal downtime. The machine incorporates advanced servo technology for precise product handling and consistent case forming, ensuring reliable performance across multiple shifts. Its modular design accommodates various infeed systems, including collation, robotic pick and place, and continuous motion systems, making it versatile enough to handle products ranging from bottles and cans to flexible packages. Safety features include fully enclosed guarding with interlocked access doors and emergency stop functions strategically positioned around the machine. The system's robust construction, combined with minimal moving parts, results in reduced maintenance requirements and enhanced operational reliability.