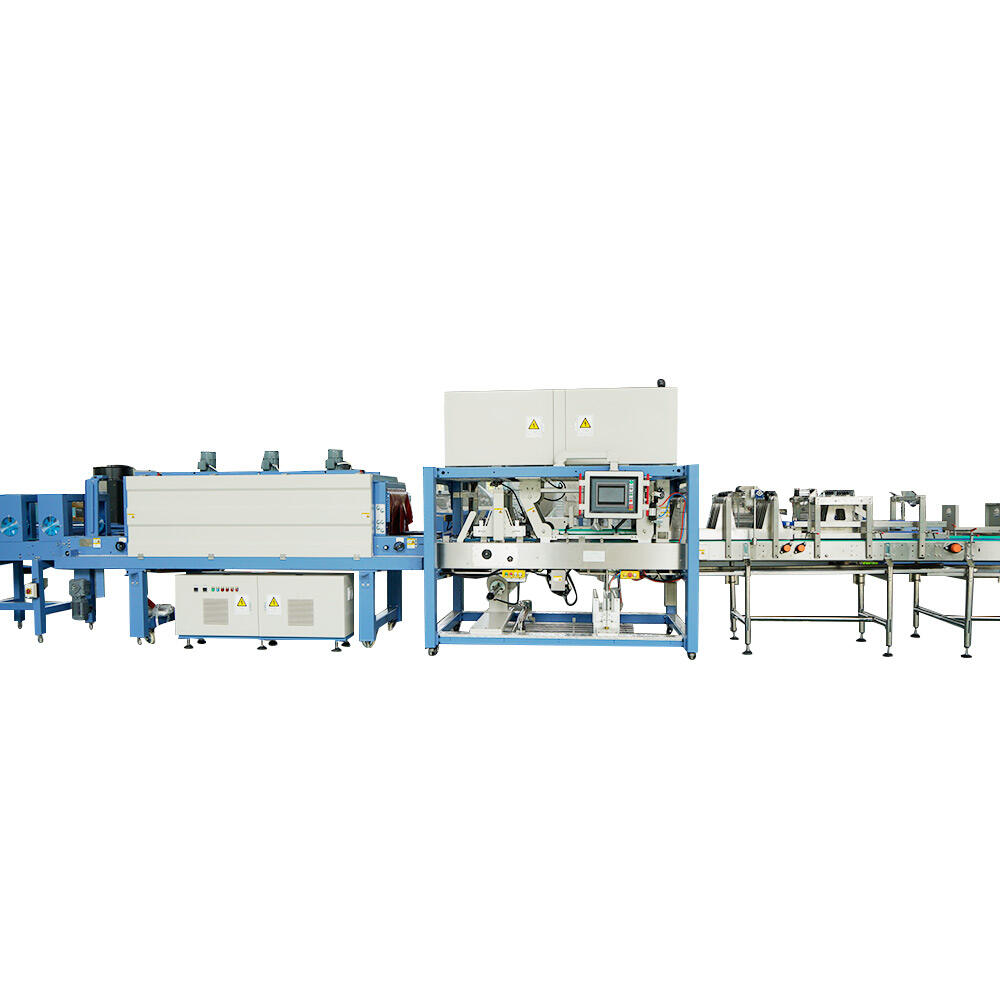

depalletizer machine for beverage line

A depalletizer machine for beverage line is an essential automated solution designed to efficiently unload and organize stacked products from pallets in beverage production facilities. This sophisticated equipment seamlessly integrates into existing production lines, handling various container types including glass bottles, plastic containers, and aluminum cans. The machine employs advanced sensors and precision controls to carefully remove layers of products while maintaining their integrity and arrangement. Operating through a combination of mechanical arms, conveyor systems, and computerized controls, the depalletizer ensures continuous product flow into the production line. Its programmable logic controller (PLC) system enables customizable operations to accommodate different product sizes and pallet configurations. The machine features safety mechanisms including emergency stops, protective barriers, and monitoring systems to prevent product damage and ensure operator safety. Modern depalletizers incorporate smart technology for real-time performance monitoring and predictive maintenance alerts, maximizing operational efficiency. These machines can handle multiple pallet sizes and product arrangements, offering flexibility for varying production needs. The system's gentle handling mechanisms prevent product damage while maintaining high throughput rates, making it indispensable for high-volume beverage operations.