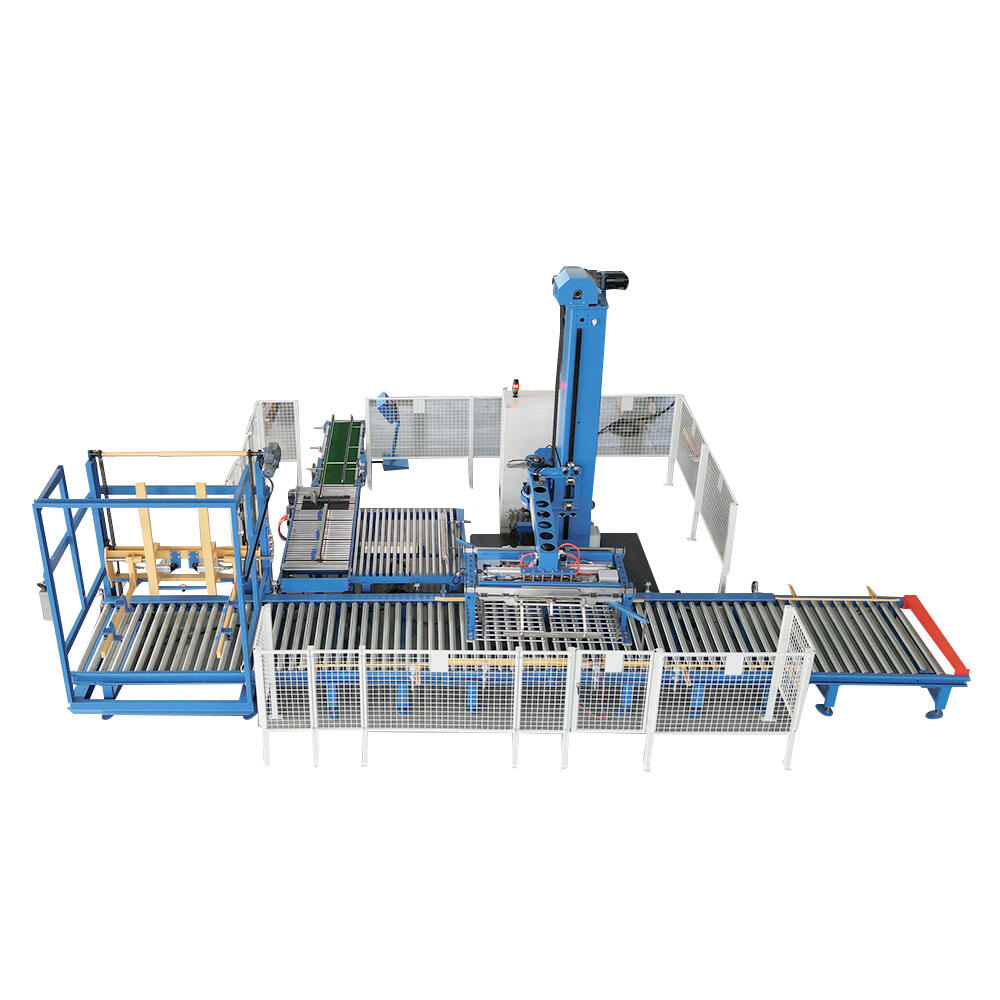

electric palletizer

The electric palletizer represents a cutting-edge solution in modern material handling and warehouse automation. This sophisticated machinery efficiently arranges and stacks products onto pallets, streamlining end-of-line packaging operations. At its core, the electric palletizer utilizes advanced servo motor technology and precision controls to ensure accurate product placement and consistent stacking patterns. The system comprises multiple components, including a product infeed conveyor, layer formation area, and pallet dispensing mechanism. Through programmable logic controllers (PLCs), the electric palletizer can handle various product sizes, weights, and stacking configurations with remarkable flexibility. The machine's electric-powered components offer superior precision compared to traditional pneumatic systems, allowing for gentler product handling and reduced energy consumption. In warehouse environments, the electric palletizer can process multiple items simultaneously, maintaining high throughput rates while ensuring product integrity. The system's advanced safety features, including light curtains and emergency stop mechanisms, protect operators while maintaining efficient operation. Modern electric palletizers also incorporate user-friendly interfaces that enable quick pattern changes and real-time monitoring of operational parameters. These machines prove particularly valuable in industries such as food and beverage, consumer goods, and manufacturing, where consistent and efficient palletizing is essential for distribution operations.