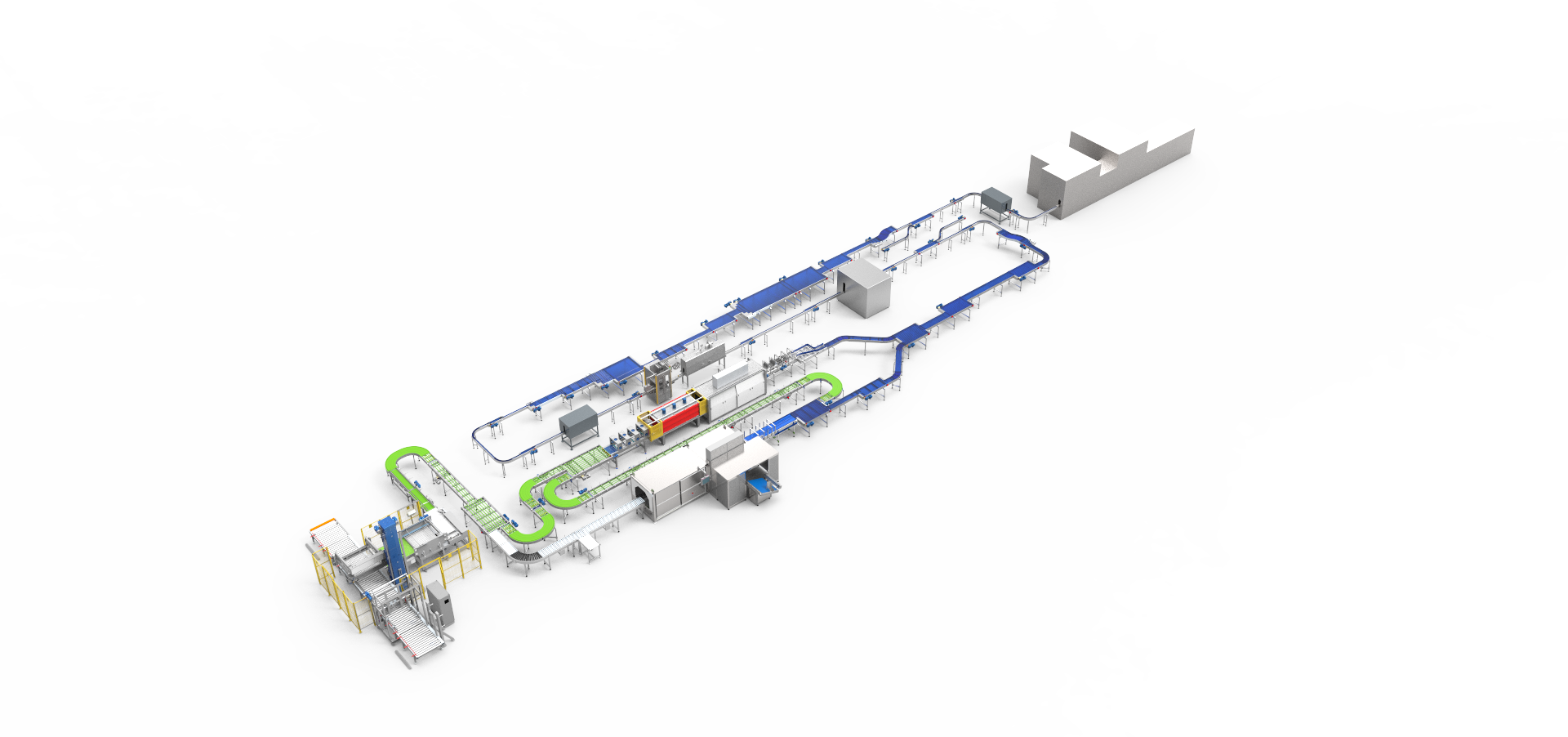

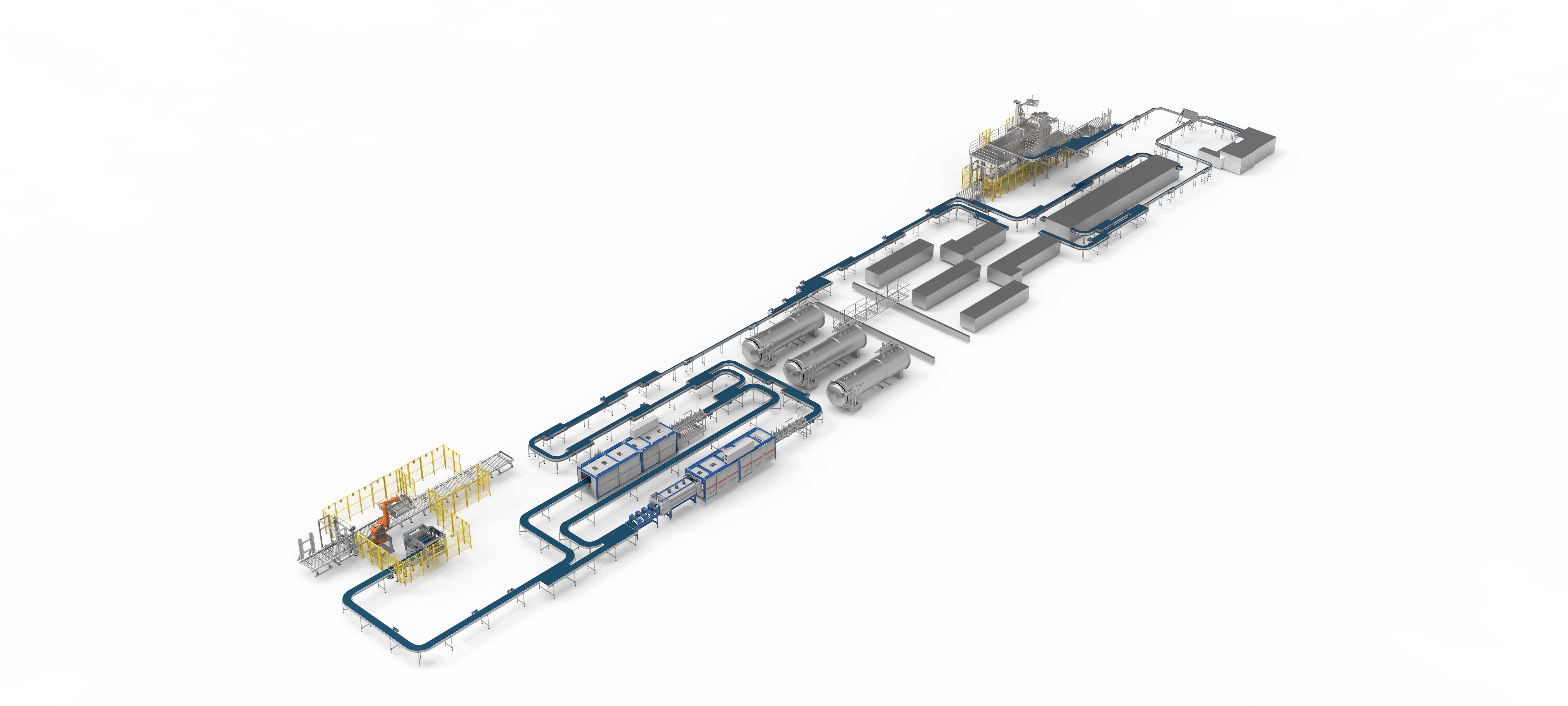

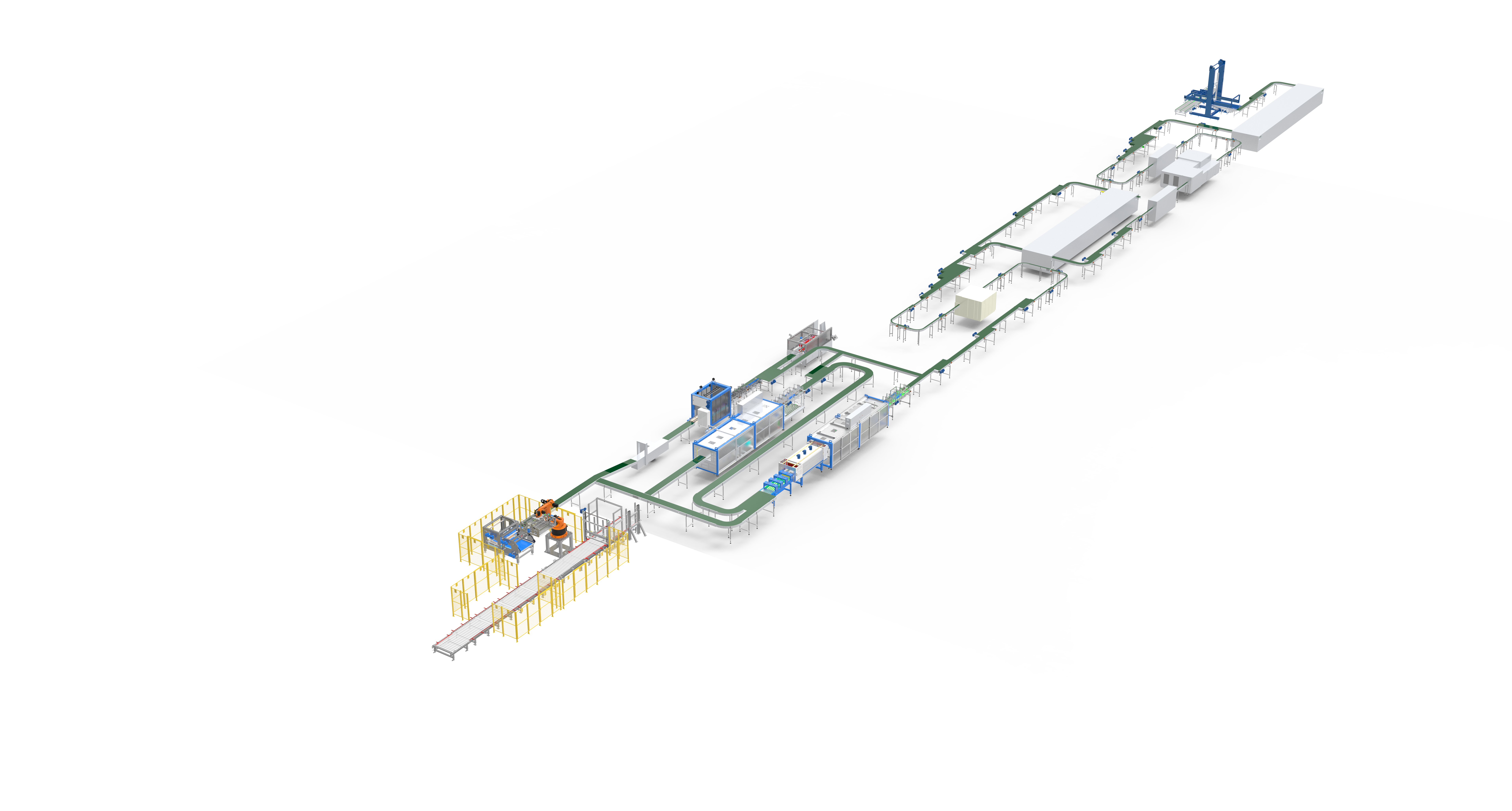

high speed beverage line

The high speed beverage line represents cutting-edge automation technology designed to meet the demanding requirements of modern beverage production. This sophisticated system integrates multiple processes including bottle washing, filling, capping, labeling, and packaging into a seamless operation capable of handling thousands of units per hour. The line incorporates advanced sensing technology and precision control systems to maintain optimal production speeds while ensuring product quality and safety. At its core, the system features state-of-the-art filling equipment that guarantees accurate liquid dispensing with minimal waste, complemented by high precision capping mechanisms that ensure proper seal integrity. The conveyor system utilizes smart routing algorithms to prevent bottlenecks and maintain consistent flow throughout the production process. Quality control stations equipped with vision systems and sensors monitor every stage of production, automatically rejecting defective products. The entire operation is managed through an intuitive central control interface that provides real-time monitoring and adjustment capabilities. Environmental considerations are addressed through energy-efficient components and water recycling systems, making it a sustainable choice for modern beverage manufacturers.