Manufacturing facilities across industries are increasingly turning to automated solutions to address rising labor costs and productivity challenges. Among these innovations, palletizing equipment stands out as a transformative technology that can significantly impact operational efficiency. Modern businesses face mounting pressure to optimize their end-of-line packaging processes while maintaining consistent quality and reducing operational expenses. The integration of automated palletizing systems represents a strategic investment that addresses multiple operational pain points simultaneously.

Understanding Modern Palletizing Technology

Core Components and Functionality

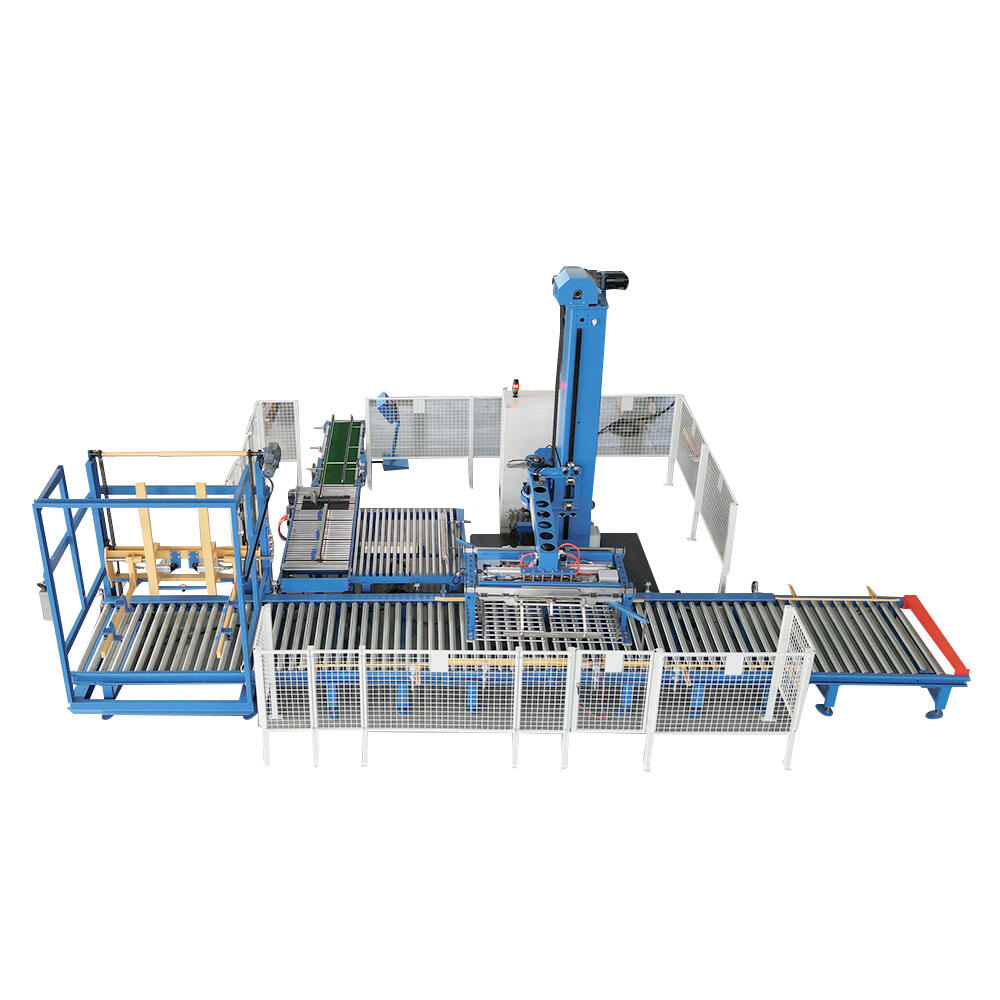

Contemporary palletizing systems incorporate sophisticated robotics, advanced sensors, and intelligent control systems to automate the stacking and arrangement of products onto pallets. These machines utilize precision engineering to handle various product types, from lightweight consumer goods to heavy industrial components. The technology combines mechanical precision with software intelligence, enabling facilities to achieve consistent pallet configurations while adapting to different product specifications and packaging requirements.

The integration of vision systems and artificial intelligence allows modern palletizing equipment to recognize product variations, adjust stacking patterns dynamically, and maintain optimal load distribution. This technological sophistication ensures that each pallet meets safety standards while maximizing space utilization and structural integrity throughout the supply chain.

Types of Palletizing Solutions

Industrial facilities can choose from several palletizing configurations, including conventional mechanical systems, robotic arms, and hybrid solutions that combine multiple technologies. Conventional systems excel in high-volume, single-product applications where consistent patterns and rapid throughput are priorities. These systems typically feature fixed motion paths and predetermined stacking sequences optimized for specific product dimensions.

Robotic palletizing systems offer greater flexibility, accommodating multiple product types and complex stacking patterns within the same installation. These systems can switch between different products and pallet configurations without extensive reconfiguration, making them ideal for facilities handling diverse product lines or frequent changeovers.

Labor Cost Reduction Through Automation

Direct Labor Savings

The implementation of a palletizer directly reduces the need for manual labor in end-of-line operations, eliminating multiple operator positions while maintaining or increasing throughput rates. Traditional manual palletizing requires multiple workers per shift to handle the physical demands of lifting, positioning, and stacking products consistently throughout the production cycle. Automated systems operate continuously without breaks, shift changes, or performance variations associated with human fatigue.

The elimination of manual handling also reduces the risk of workplace injuries, particularly repetitive strain injuries and back problems commonly associated with heavy lifting operations. This reduction in injury rates translates to lower workers' compensation costs, reduced absenteeism, and decreased turnover in physically demanding positions.

Indirect Cost Benefits

Beyond direct labor elimination, automated palletizing systems contribute to significant indirect cost savings through improved operational consistency and reduced supervisory requirements. Automated systems require minimal oversight once properly configured, allowing supervisory personnel to focus on higher-value activities rather than monitoring repetitive manual tasks.

The consistency of automated operations also reduces product damage during the palletizing process, minimizing waste and rework costs. Manual palletizing operations often result in inconsistent stacking patterns, damaged products, and unstable loads that can cause problems during transportation and storage.

Productivity Enhancement Through Automation

Throughput Optimization

Modern palletizing systems consistently outperform manual operations in terms of speed and reliability, often achieving throughput rates that exceed manual capabilities by significant margins. These systems operate at consistent speeds without the performance variations associated with human operators, maintaining optimal cycle times throughout extended production runs.

The precision of automated systems also enables tighter integration with upstream production equipment, creating seamless material flow from manufacturing through packaging and palletizing. This integration eliminates bottlenecks and reduces the buffer inventory typically required between manual operations and automated production lines.

Quality and Consistency Improvements

Automated palletizing systems deliver consistent pallet configurations that meet predetermined specifications for load stability, weight distribution, and dimensional accuracy. This consistency improves downstream operations including warehousing, transportation, and customer receiving processes by ensuring predictable pallet characteristics.

The elimination of human variability in stacking patterns also improves space utilization in warehouses and transportation vehicles, as consistent pallet dimensions enable more efficient storage and loading configurations. These improvements contribute to reduced logistics costs and improved customer satisfaction through more reliable delivery schedules.

Implementation Considerations and Return on Investment

Initial Investment and Payback Analysis

The capital investment required for palletizing automation varies significantly based on system complexity, throughput requirements, and integration needs. However, most facilities experience payback periods ranging from 18 to 36 months when factoring in direct labor savings, reduced injury costs, and productivity improvements.

The financial analysis should consider not only the equipment cost but also installation, training, and integration expenses. Many suppliers offer financing options and lease arrangements that can improve cash flow while enabling facilities to realize immediate operational benefits from automated palletizing systems.

Integration and Operational Considerations

Successful palletizing automation requires careful consideration of existing facility layout, product characteristics, and downstream handling requirements. The integration process typically involves modifications to material handling systems, control system programming, and operator training to ensure optimal performance.

Facilities should also consider maintenance requirements and spare parts availability when selecting palletizing equipment. Modern systems feature diagnostic capabilities and remote monitoring options that enable proactive maintenance scheduling and minimize unplanned downtime.

Industry Applications and Success Stories

Manufacturing Sector Applications

Food and beverage manufacturers have widely adopted palletizing automation to handle diverse product types while maintaining strict hygiene standards. These applications often require specialized equipment designed for washdown environments and food-grade materials that comply with industry regulations.

Chemical and pharmaceutical industries utilize palletizing systems to handle hazardous materials safely while maintaining precise documentation and traceability requirements. Automated systems reduce human exposure to dangerous substances while ensuring consistent handling procedures that meet regulatory compliance standards.

Distribution and Logistics Centers

Distribution centers and logistics facilities implement palletizing automation to manage high-volume operations with varying product mixes and customer-specific requirements. These applications often feature flexible robotic systems capable of handling multiple SKUs and creating mixed pallets according to order specifications.

The ability to operate continuously during peak shipping periods provides significant advantages in meeting delivery commitments and managing seasonal demand fluctuations. Automated systems maintain consistent performance levels regardless of external pressures or staffing challenges.

Future Trends and Technology Evolution

Artificial Intelligence Integration

Emerging palletizing technologies incorporate artificial intelligence and machine learning capabilities that enable systems to optimize stacking patterns based on product characteristics and stability requirements. These advanced systems learn from operational data to improve performance continuously and adapt to changing product specifications.

Predictive maintenance capabilities utilizing IoT sensors and data analytics help prevent unplanned downtime while optimizing maintenance schedules based on actual equipment condition rather than predetermined intervals. This approach reduces maintenance costs while improving overall equipment effectiveness.

Collaborative Robotics and Flexibility

The development of collaborative robotic systems enables safer human-robot interaction in palletizing applications, allowing operators to work alongside automated systems when necessary. These systems feature advanced safety sensors and programming that automatically adjust operation when humans enter the work area.

Modular palletizing systems offer increased flexibility for facilities with changing production requirements, enabling reconfiguration and expansion without complete system replacement. This adaptability provides long-term value as business needs evolve and production volumes change.

FAQ

What is the typical payback period for palletizing automation investment?

Most facilities experience payback periods between 18 and 36 months for palletizing automation investments. The actual timeframe depends on current labor costs, production volume, and the complexity of the automated system. Higher-volume operations with significant manual labor costs typically achieve faster payback periods, while facilities with moderate volumes may require longer periods to realize full return on investment.

Can automated palletizing systems handle different product types and sizes?

Modern robotic palletizing systems offer excellent flexibility in handling various product types, sizes, and packaging formats within the same installation. These systems can switch between different products through software programming changes rather than mechanical reconfiguration. However, the range of products that can be handled depends on the specific system design and gripper technology selected during the initial installation.

What maintenance requirements are associated with automated palletizing equipment?

Automated palletizing systems require regular preventive maintenance including lubrication, sensor calibration, and wear component replacement. Most modern systems feature diagnostic capabilities that monitor component condition and predict maintenance needs. Typical maintenance schedules include daily visual inspections, weekly lubrication points, and monthly detailed inspections, with major service intervals occurring every 6 to 12 months depending on operating conditions and throughput.

How does palletizing automation affect product quality and damage rates?

Automated palletizing systems typically reduce product damage rates compared to manual operations through consistent handling procedures and precise positioning control. The elimination of human variability in lifting and placement reduces the risk of dropped products, misaligned packages, and unstable load configurations. Additionally, automated systems can be programmed to optimize stacking patterns for maximum stability during transportation and storage, further reducing damage throughout the supply chain.

Table of Contents

- Understanding Modern Palletizing Technology

- Labor Cost Reduction Through Automation

- Productivity Enhancement Through Automation

- Implementation Considerations and Return on Investment

- Industry Applications and Success Stories

- Future Trends and Technology Evolution

-

FAQ

- What is the typical payback period for palletizing automation investment?

- Can automated palletizing systems handle different product types and sizes?

- What maintenance requirements are associated with automated palletizing equipment?

- How does palletizing automation affect product quality and damage rates?